Knowledge

Lab Report XRF 457 Analyzing thin layers under vacuum

The analysis of thin layers or coatings is a common task in Micro-XRF spectrometry. Both the non-destructive operation

Lab Report XRF 457 Analyzing thin layers under vacuum

The analysis of thin layers or coatings is a common task in Micro-XRF spectrometry. Both the non-destructive operation of the method and the ability of X-rays to penetrate into sample and obtain information on the material beneath the surface make this method attractive or the purpose of analyzing single or multiple layers. The special challenge in analyzing the samples discussed here is that both layer (aluminum) and substrate (silicon) are light elements, which requires measurement under vacuum, because otherwise the air in the beam path between sample and detector would absorb the low energy radiation emitted by the sample. Additionally, this lab report compares manual and automated analysis using Auto-Point.

Instrumentation

The measurements were performed with a Bruker M4 TORNADO. This Micro-XRF spectrometer is equipped with a large vacuum sample chamber and uses a focused X-ray beam (spot size < 20 μm) to induce fluorescence in the sample. This signal is analyzed with an energy dispersive detector.

The M4 TORNADO combines high spatial resolution with fast data processing and a high speed motorized XYZ-stage for sample positioning.

Measurement conditions

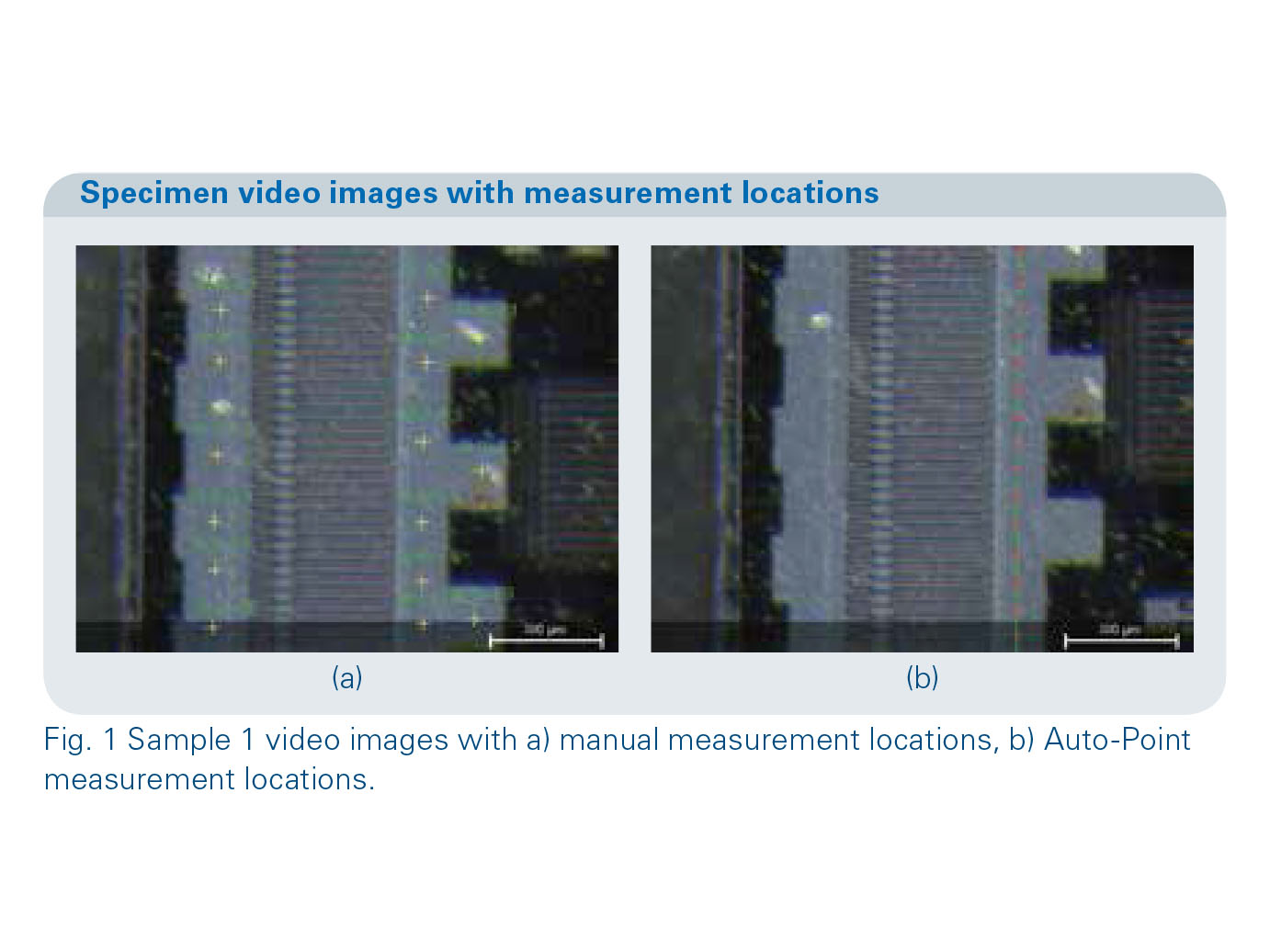

The X-ray tube settings used for the analysis were 50 kV and 200 μA. The samples were measured at a pressure of 20 mbar. 15 measurements were performed on each sample, the acquisition time for the manual measurements was 60 s. Automated measurements took place using Auto-Point, setting point number to 20 and point distance to 70 μm. Acquisition time for the automated measurements was shortened to 10 s per points. Fig. 1 a) and b) shows the location of manual measurement spots and some of the Auto-Point spots on sample 1.

Results

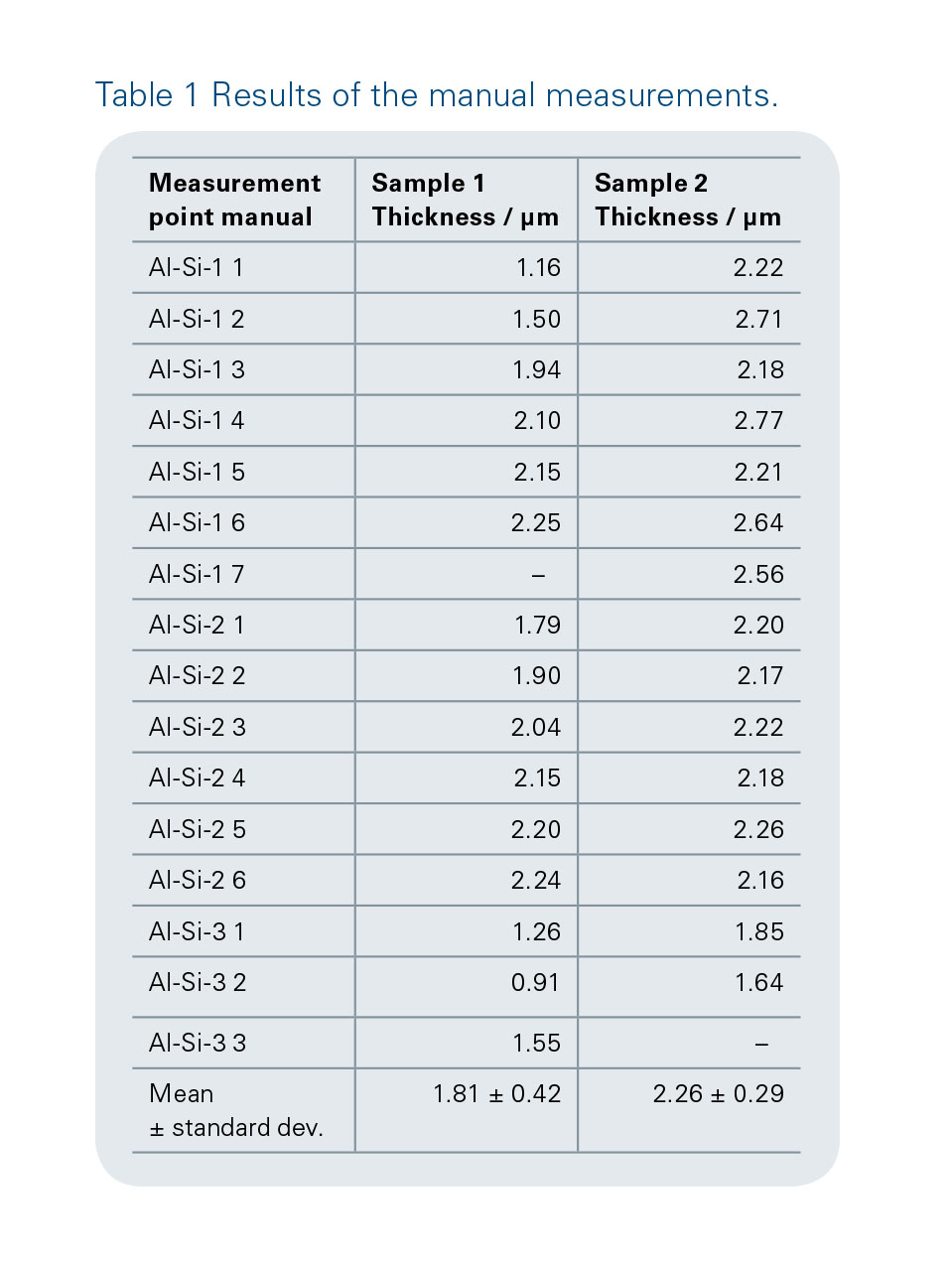

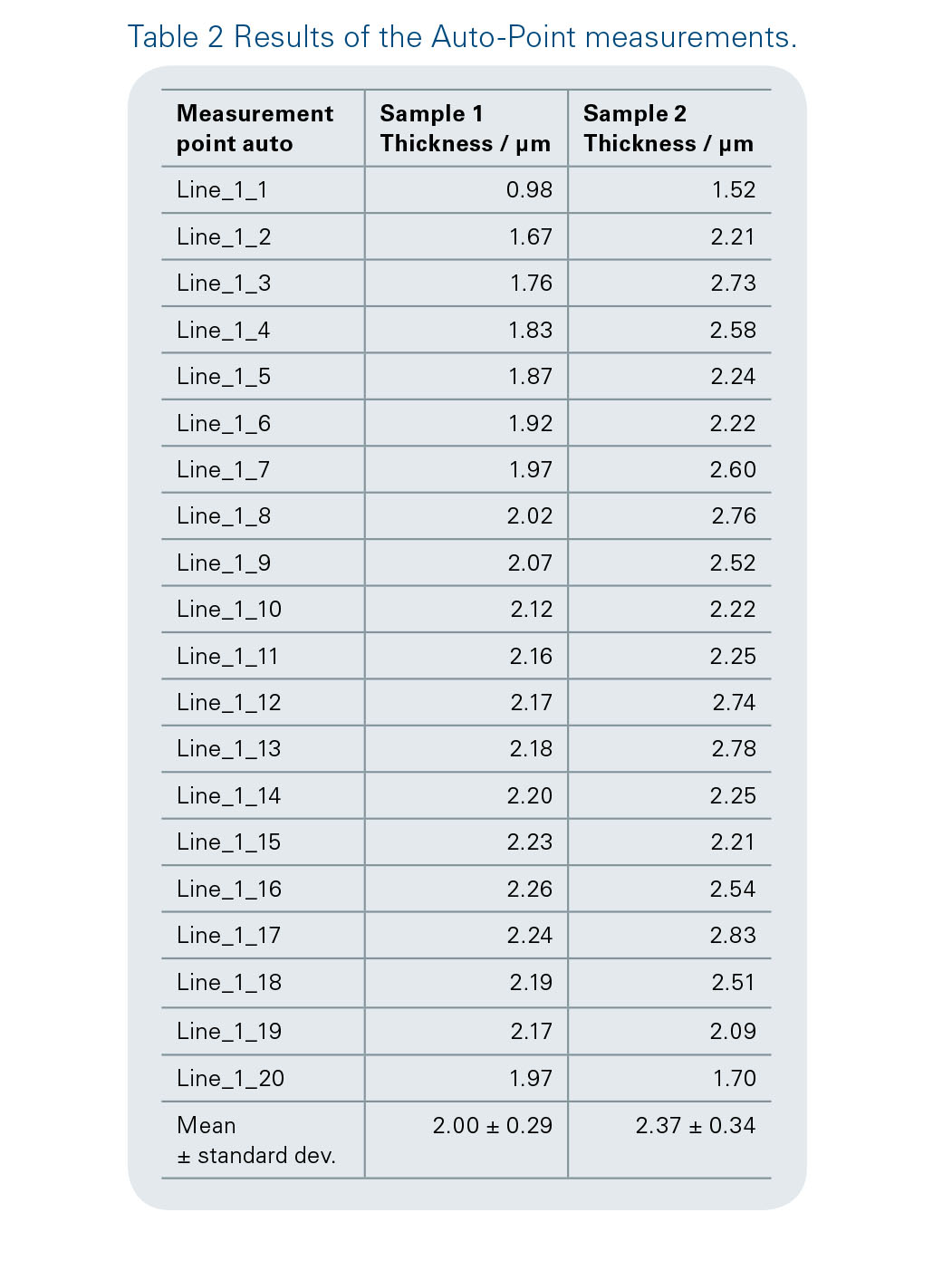

As the numbers in Table 1 and Table 2 show, the thickness of the layers is around 2 μm, as it is supposed to be. Although it is difficult to compare the results of the manual and the automated measurements due to the variations in the measured values and measurement locations, there is an indicator that the sample 2 layer is thicker than the that the shorter acquisition time of automated measurements suffices for reliable results.

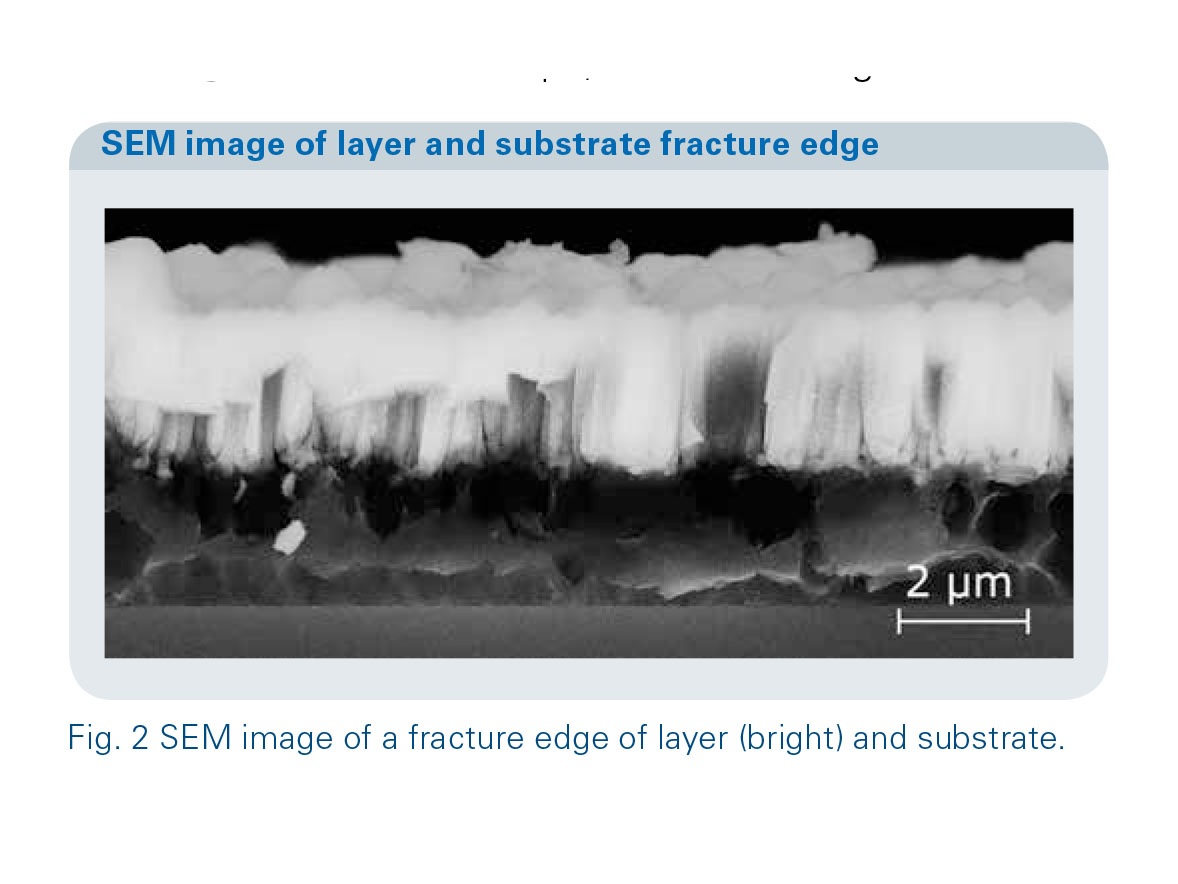

The results obtained with the M4 layer quantification routine are verified by measurements on a fracture edge in the scanning electron microscope, as shown in Fig. 2.

Conclusion

This example shows that Micro-XRF is a fast and accurate means to measure layer thicknesses at arbitrary locations on a sample non-destructively. The vacuum option extends the analytical range to light elements in layers and substrate.

Credit : Bruker Co., Ltd.

Contact us

388/5 Nuanchan Road, Nuanchan,

Buengkum, Bangkok 10230

0 2363 8585 (auto)

0 2363 8595

081 498 9939