Knowledge

Analysis of jewelry alloys with M1 ORA and M1 MISTRAL

The monetary value of jewelry alloys is mainly determined by their content of precious metals.

Analysis of jewelry alloys with M1 ORA and M1 MISTRAL

The monetary value of jewelry alloys is mainly determined by their content of precious metals. That is why elementalanalysis of this kind of samples is of extreme importance. The high value of the samples, their intricate nature and the often inhomogeneous composition pose following requirements for the analytical method:

• high precision and accuracy

• non-destructive analysis, if possible

• small spot size for analysis of rough surfaces

• determination of all components of the alloy, even unex pected elements.

Several methods have been developed for the analysis of precious metal alloys. One of the standard techniques is fireassay, which offers extremely high precision and accuracy. However, this method has various disadvantages: it is destructive, time consuming and produces a high amount of toxic waste.

Conventional X-ray fluorescence (XRF) spectroscopy could be used for this analytical task, but the analyzed area would be too large - with diameters in the range of 10 to 60 mm. The development of micro-XRF methods, where small sample areas down to 0.1 mm can be analyzed, offers new possibilities for this application.

Instrumentation

The spectrometers M1 MISTRAL and M1 ORA are micro-XRF devices. The small spot size of 0.3 to 1.5 mm is generated by a collimator system. The excitation is provided by a side window X-ray tube with max. 50 kV and 40 W. The fluorescence radiation is detected with energy dispersive detectors: a proportional counter (PC) is used for quality control purposes and a silicon drift detector (SDD) if analysis of unknown samples and traces is required.

The PC has a large sensitive area that can collect a high amount of fluorescence radiation and keeps the statistical error low. However, this detector has a limited energy resolution that allows only the analysis of samples with known qualitative composition. In contrast, the high energy resolution of the SDD permits the analysis of completely unknown samples and even small concentrations down to the ppm-range. Therefore, it can be used in hallmarking offices and refineries, even to examine traces.

The easy to use software makes the instruments accessible also to the non-expert operator. The large sample chamber, the optional motorized sample stage with autofocus function, the optical microscope for exact positioning of measuring spot, the intuitive XSpect software, the direct calculation of weight concentrations and karatage together with averaging of repeated measurements - all these features make the analysis easier.

Results

The analytical performance is determined by the repeatability, the stability of the instrument and by the accuracy of the analysis. For these instruments, excellent repeatability and stability are guaranteed through repeated tests. These parameters are so almost exclusively defined by the statistical error of the measurement.

For example, the analysis of a sample through single measurements of 60 seconds repeated over 75 hours has a statistical error of 0.144 % and a relative standard deviation of 0.143 %. This is an important prerequisite for high accuracy.

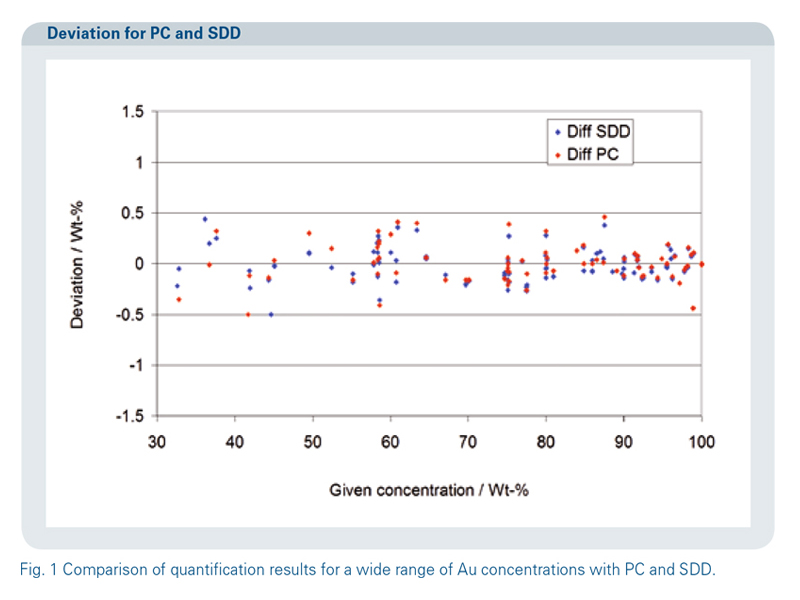

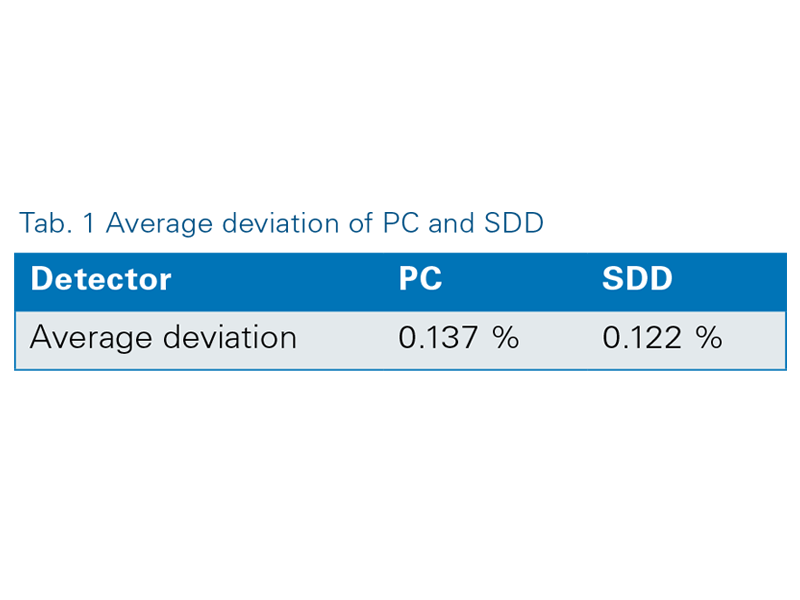

Both standardless and standard-based quantification routines can be applied. The standard-based quantification method achieves higher accuracy, although this also depends on the type of detector. Figure 1 shows the quantification results for Au concentrations. The average deviation of both types of detectors is displayed in table 1.

The results show that the PC’s larger sensitive area and the resulting higher intensity are compensated by the SDD’s shorter sample-detector distance and smaller peak fitting error derived from less peak overlapping.

Conclusion

Micro-X-ray fluorescence is a good analytical tool for the analysis of jewelry samples. Non-destructivity leaves the sample unharmed, simultaneous detection of all elements allows a complete characterization of the material and the small spot size permits the analysis of irregular and inhomogeneous samples. The achieved accuracy is not as high as with fire assay, but it is sufficient for quality control of jewelry manufacturing, screening of unknown samples and detection of traces down to the ppm-range.

Credit : Bruker Co., Ltd.

Contact us

388/5 Nuanchan Road, Nuanchan,

Buengkum, Bangkok 10230

0 2363 8585 (auto)

0 2363 8595

081 498 9939