Advance Analytical

เครื่องมือวิเคราะห์ทางวิทยาศาสตร์ขั้นสูง Advance Analytical

Thermomechanical analysis (TMA) is used to measure dimensional changes of a material as a function of temperature. Thermal expansion and effects such as softening, crystallization and solid-solid transitions determine the potential applications of a material and provide important information about its composition. Viscoelastic behavior can be studied by varying the applied force (DLTMA mode).

Precise Determination of Coefficients of Thermal Expansion (CTEs) and Transitions.

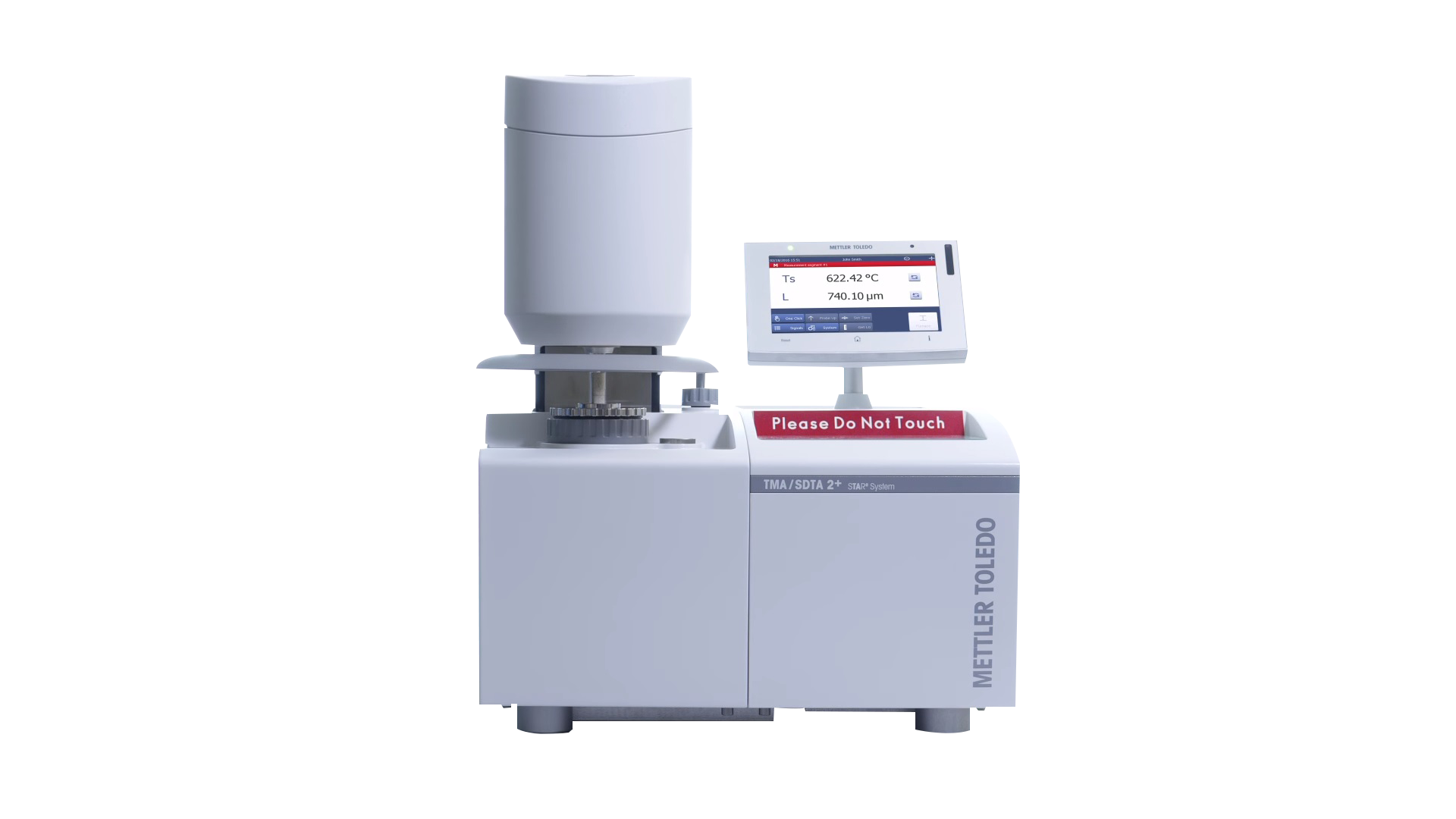

The TMA/SDTA 2+ can be used for a wide range of applications due to its broad temperature range and the wide choice of force parameters in compression and tension modes. As a result, the TMA/SDTA 2+ quickly provides characteristic information on numerous types of samples, for example very thin layers, large sample cylinders, fine fibers, films, plates, soft or hard polymers, and single crystals.

Thermomechanical analysis (TMA) is the ideal addition to DSC. Besides the measurement of expansion coefficients, TMA is also an excellent technique for determining glass transitions that cannot be satisfactorily measured by DSC, for example materials with a high filler content. The penetration mode is ideal for characterizing the glass transitions of difficult samples such as very thin coatings.

Features and benefits of the METTLER TOLEDO TMA/SDTA 2+:

- Wide temperature range – from –150 to 1600 °C

- SDTA – for the simultaneous measurement of thermal effects

- One Click™ – provides efficient sample measurement

- Nanometer resolution – allows very small dimensional changes to be measured

- Dynamic load TMA (DLTMA mode) – measures weak transitions and elasticity

- Wide measurement range – for small and large samples

- Modular design – allows future expansion to meet new requirements

- Hyphenated techniques – for Evolved Gas Analysis using MS, GC-MS, or FTIR

SDTA Signal - Unsurpassed Temperature Accuracy

One Click™ Technology

Contact us

388/5 Nuanchan Road, Nuanchan,

Buengkum, Bangkok 10230

0 2363 8585 (auto)

0 2363 8595

081 498 9939