Mlab 200R

LASER METAL 3D PRINTING EFFICIENCY FOR HIGH SURFACE QUALITY PARTS

"The Mlab 200R is perfectly suited for high-surface quality and creating the finest part structures. In addition, this machine allows you to manufacture large parts with much greater productivity—without the machine losing any of its familiar compactness."

The Mlab 200R boasts a new user-oriented design, with a larger build envelope (54% more build volume), a higher laser power of 200 watts and a space-efficient footprint. In addition, the new machine includes a larger filter, resulting in longer filter lifespans, and a clamping system which enables more accurate component positioning.

Special features are the water-floodable filter and the modular structure of the machine. The process chamber and handling station are physically separate and enable safe and easy component handling. All process steps take place under inert gas, shielded from external influences. The whole process can therefore be implemented reliably and with the maximum quality level.

Features

- Modular system for three different build volumes

- Perfectly suited for high surface quality and fine part structures

| Powders available | Parameters available |

|

|

| Laser Power | Build volume |

|

Fibre laser 200 W (cw) |

50 x 50 x 80 mm (x,y,z) 70 x 70 x 80 mm (x,y,z) 90 x 90 x 80 mm (x,y,z) 100 x 100 x 100 mm (x,y,z) |

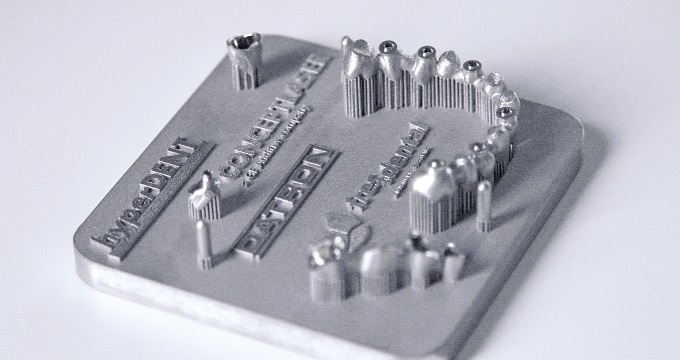

We are transforming the dental industry and offer with our partners Follow-Me, Datron and Fresdental a dental hybrid manufacturing solution, which combines the advantages of additive manufacturing with subtractive technology, to get the best out of both manufacturing worlds.