Knowledge

Xylene Soluble Content in Polypropylene & further Polymer Applications

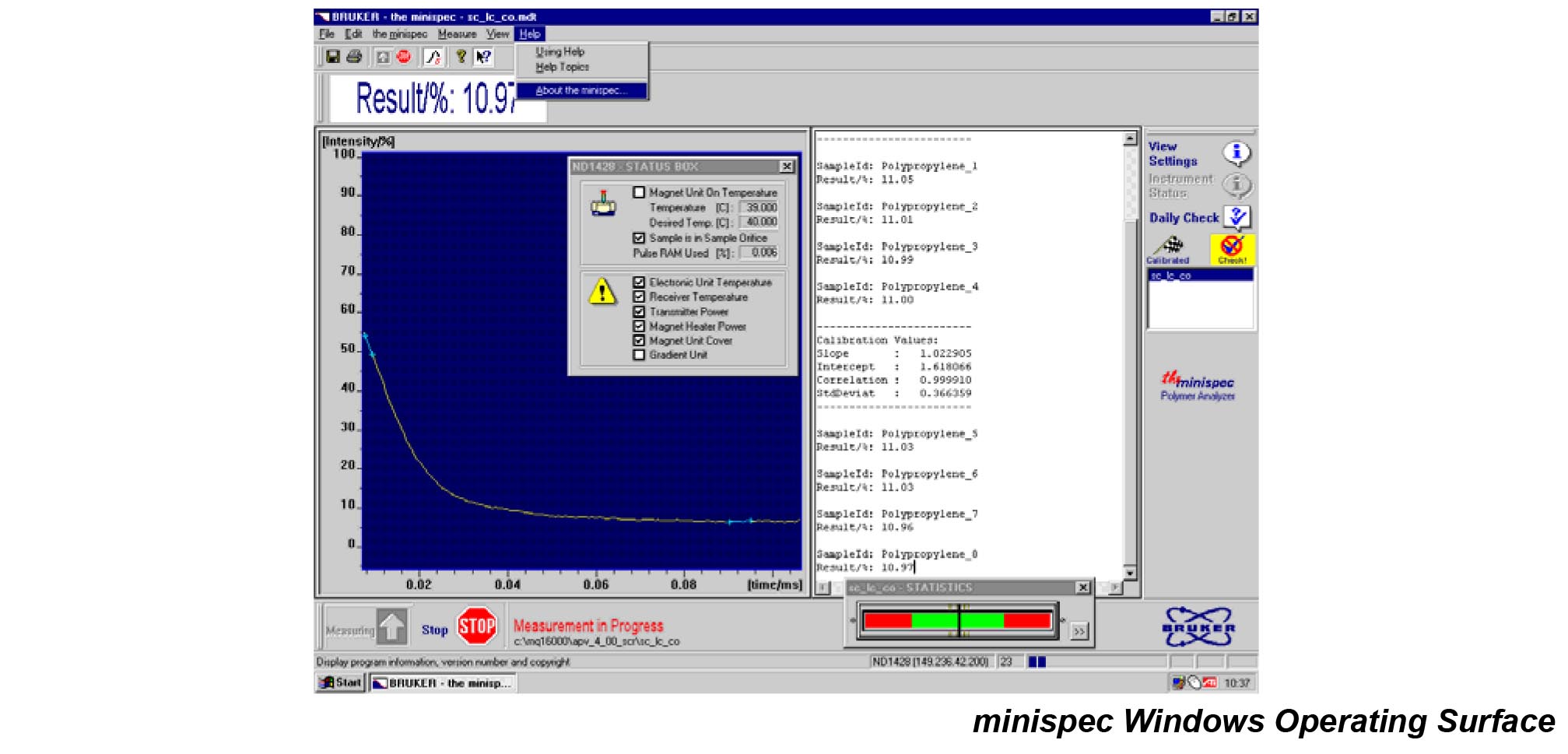

Minispec Analysis can be analysis Xylene Soluble Content in PP and total time of analysis less than 10 minutes

The minispec Xylene Soluble Application - Applied in Polypropylene Facilities world-wide.

Wherever Polypropylene is produced around the world, the Bruker minispec is present and does its job to the full satisfaction of the plant leaders. The old-fashioned classical chemical method with xylene as a solvent is almost replaced by up to date minispec NMR technology.

The amount of short chain Polypropylene characterises the Polypropylene product and it is therefore essential to know how big this fraction is. The classical method removed this portion by adding xylene and dissolving these molecules from the rest of the samples. However this procedure requires hours and skilled personnel and is not suitable for production control.

Big Polypropylene plants require this important sample parameter within every ten minutes in order to guarantee that the product delivered was always inside specs. Therefore the quick minispec analysis (no sample preparation / untrained personnel / no solvents / total time of analysis less than 10 minutes) is a must.

Further minispec Applications in the Polymer Field

• Ethylene Content in Polypropylene

• Tacticity in Polypropylene

• Additive Content in Polypropylene

• Density & Crystallinity of Polyethylene

• Cross-Link Density of Polymers

• Melt-Flow Indices of Polymers

• Molecular Weights of Polymers

• Solid Content & Viscosity of Polystyrene

• Rubber Content in Polymers

All analysis on powders, pellets and granulates.

Introduction to minispec Theories - the Ratio Applications

Placing hydrogen nuclei into an external magnetic field leads to a resulting magnetisation in field direction. The size of this magnetisation can be measured by applying a RF pulse and turning the magnetisation by 90°. Directly after the pulse the magnetisation will return back to its equilibrium position, thus creating a decreasing signal in the detection system of the NMR unit, called the relaxation process.

The Polypropylene application benefits from exactly this relaxation behaviour, meaning that solid or stronger bounded fractions of the sample will return faster to the equilibrium state than the disordered portions.

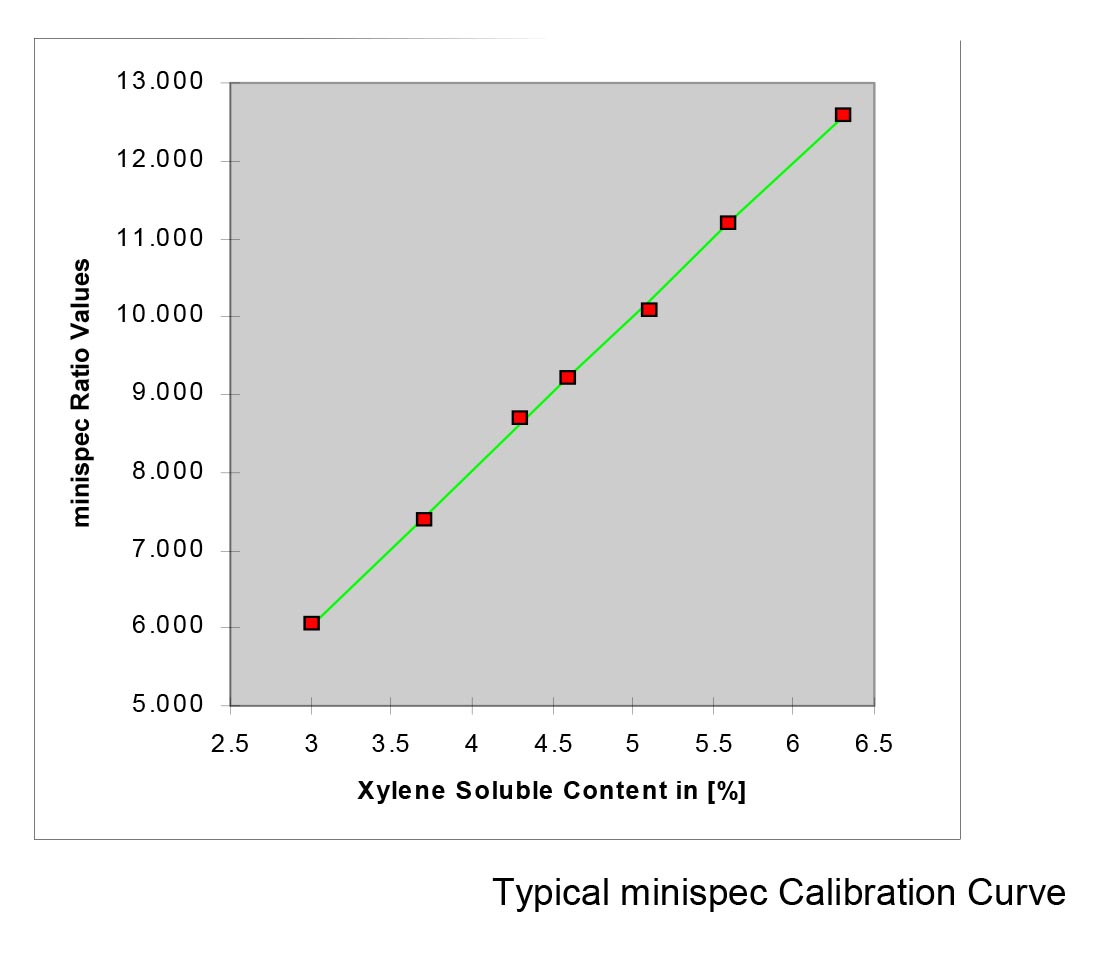

Checking this decay signal at two characteristic times will provide a ratio (ratio application) that is characteristic for the xylene soluble content in the Polypropylene sample. Also Ethylene as an additive can be analysed with exactly this method.

After relaxation has completed, the sample is in exactly the same state as before the NMR analysis, thus demonstrating the non-invasive character of this analysis.

minispec Calibration Curve Generation

Following the explanations on the left side, the minispec calculates different ratios of signal amplitudes for different Polypropylene samples. The ratios calculated are not exactly the xylene soluble values (different proton densities etc.), but correlate with them in a simple linear relationship. Using a few well-known samples of PP (3 - 5) will allow calibration of the minispec, meaning that NMR values are related to xylene values. Finally a linear regression is activated and afterwards the minispec is ready for analysis of unknown Polypropylene samples.

Credit : Bruker

Contact us

388/5 Nuanchan Road, Nuanchan,

Buengkum, Bangkok 10230

0 2363 8585 (auto)

0 2363 8595

081 498 9939