Knowledge

Spin Finish on Fibers Oil Pick Up with Sample Weighing

Spin Finish is added to fibers to improve their downstream handling in the process of manufacturing.

Spin Finish on Fibers Oil Pick Up with Sample Weighing Fast and Reliable Quality Control Fast and Reliable Quality Control

Spin Finish is added to fibers to improve their downstream handling in the process of manufacturing.Fibers with properly distributed Spin Finish run more smoothly through the spinning machines allowing faster and more reliable operation. Spin Finish avoids static electricity, guarantees sufficient lubrication and improves the cohesion of filaments. Determining the Spin Finish levels is crucial and needs to be assessed quickly and continuously. The minispec has proven to be the best solution for analyzing practically all combinations of fibers and Spin Finishes.For high Spin Finish concentrations, see also our application note”Spin Finish on Fibers – Oil Pick Up without Sample Weighing

Features and Benefits

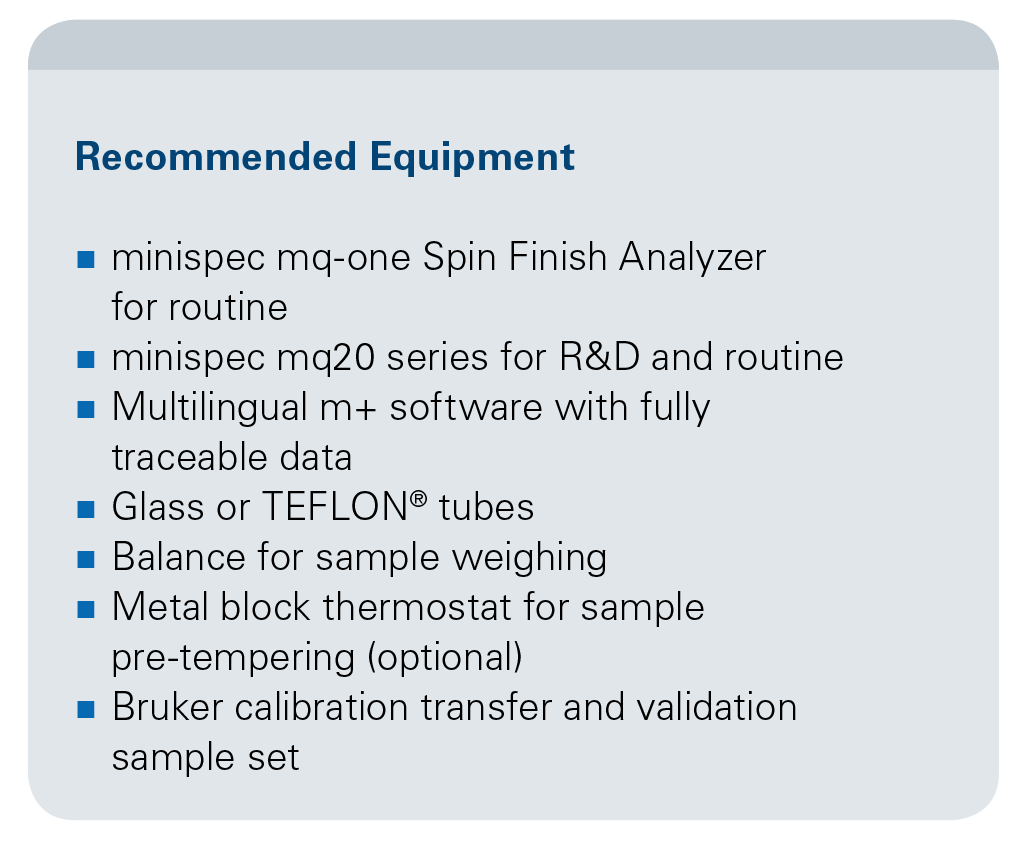

- Set of Bruker Calibration Transfer and Validation Samples provided

- Very few calibration samples necessary (3 – 5)

- Independent from sample color, surface or yarn count

- No solvent required

- More reproducible than wet chemistry

Applicable Material

- Technical textile and high performance fibers

- Multi-filament, monofilament, staple fibers, non-woven fabrics, texturized samples

- Polyester, polyamide, polypropylene, polyethylene, polyacrylonitrile fibers and yarns

Application Method

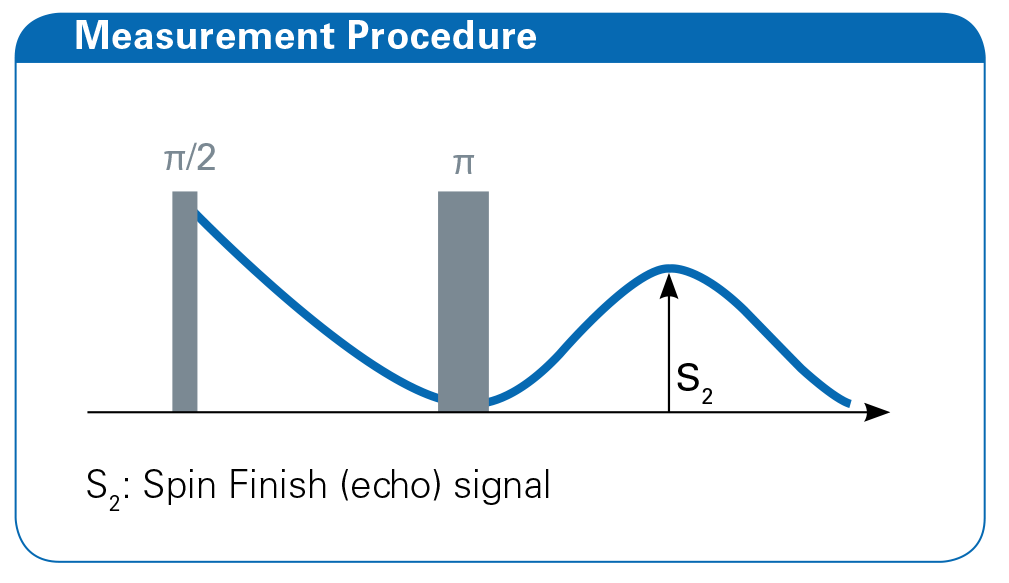

The time-domain (TD) NMR signal of a fiber sample exhibits different components. Fibers, moisture and Spin Finish are each characterized by a typical decay behavior. The NMR signal of Spin Finish is well separated from the other signals and can be quantitatively analyzed. For the application Spin Finish on Fibers with Sample Weighing a Hahn echo pulse sequence is applied and the weight-normalized echo signal amplitude (S2) correlates with the Spin Finish concentration.

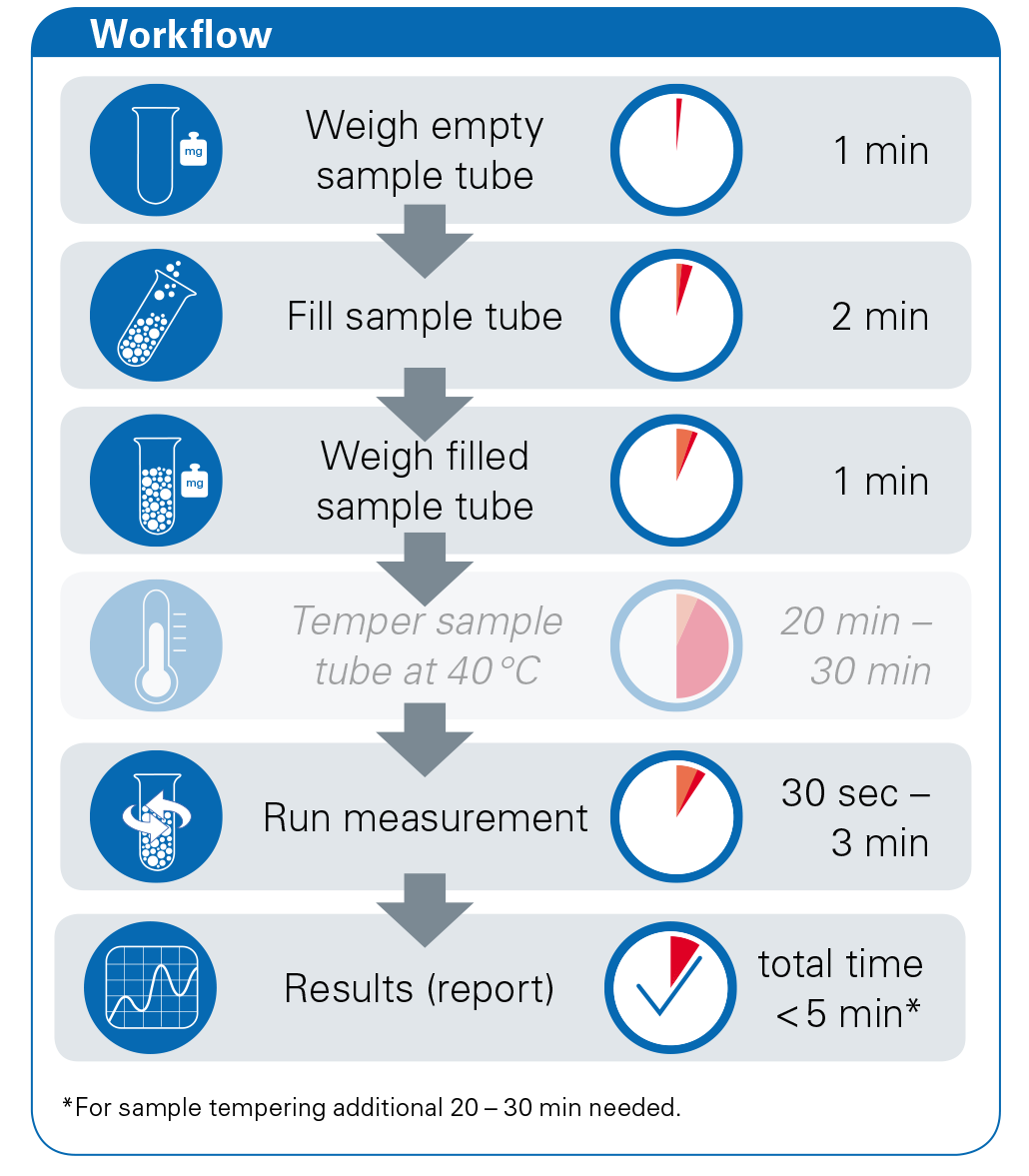

Note: This method requires the weighing of the fiber sample.

Note: This method requires the weighing of the fiber sample.

Make sure to use dry fibers and to fill the tube not higher than the active volume.

The average sample mass depends on the kind of fibers and the detection limit on the amount of fibers measured.

Calibration

- Spin Finish concentrations range from 0.1 % to 5 %

- Very low Spin Finish concentrations, 0.02 % – 0.1 % can be measured as well, but require longer measurement times and sample optimized parameters

Calibration can be done by using well-known reference values (e.g. Spin Finish results from extraction) or by adding defined masses of Spin Finish for a fiber-free Spin Finish. Alternative calibrations for respective Spin Finish and eventually for respective fibers are recommended, but not necessary in all cases. Bruker offers a set of 8 samples to either save a calibration, to transfer it to another system, or to use it for the validation of a Spin Finish calibration.

Credit: Bruker

Contact us

388/5 Nuanchan Road, Nuanchan,

Buengkum, Bangkok 10230

0 2363 8585 (auto)

0 2363 8595

081 498 9939