Knowledge

Crystallinity & Density of Polyethylene

The crystallinity of polyethylene (PE) determines the stiffness, the impact and tensile strength

Crystallinity & Density of Polyethylene

Process Monitoring and Quality Control

The crystallinity of polyethylene (PE) determines the stiffness, the impact and tensile strength, the permeability and the resistance of the material. Therefore, its measurement is of paramount importance regarding the specifications of a PE grade. Bruker’s PE crystallinity application provides this information fast, with high precision and repeatability. Other commonly employed methods such as Differential Scanning Calorimetry (DSC) or density determination by displacement are significantly slower and require tedious sample preparation. The analysis can be carried out at line by untrained personnel requiring no dedicated lab environment.

The obtained crystallinity correlates to the density measured with:

- ISO 1183 / ASTM D1505 (method by titration / displacement / pycnometer)

- ASTM D792 (displacement method)

- ASTM D4883 (ultrasound)

Features and Benefts

- QC of product specifications

- At line measurement

- Minimal sample preparation (pellets and powders are measured as is)

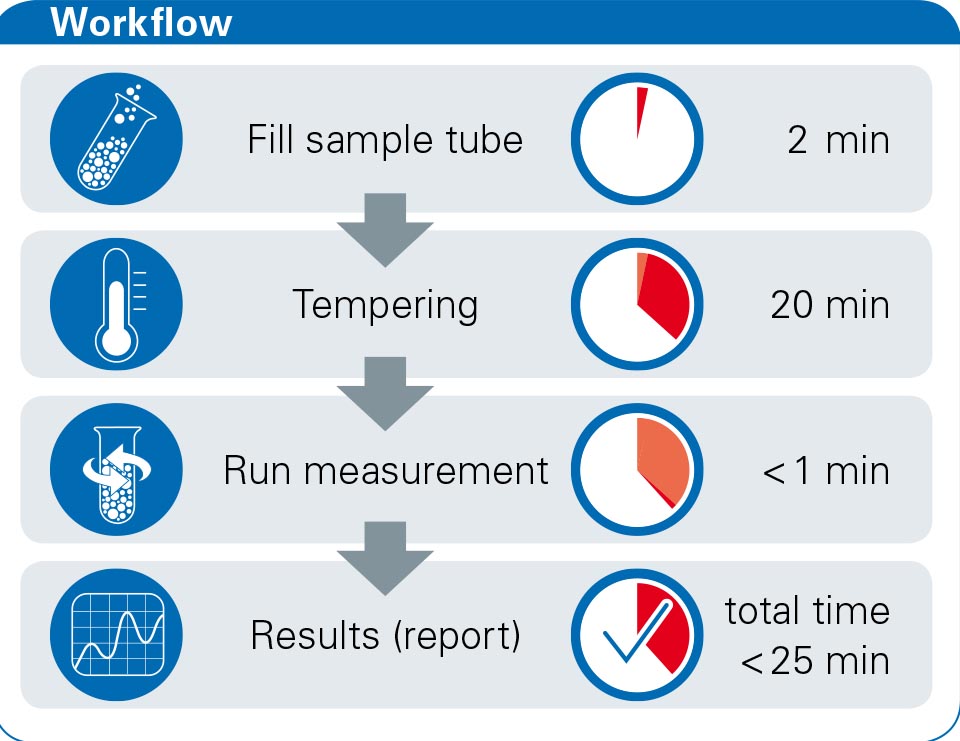

- 25 min. from taking the sample to validated result

- Daily check instrument validation

Applicable to all PEs

- UHMWPE – Ultra High Molecular Weight Polyethylene

- HDPE – High Density Polyethylene

- MDPE – Middle Density Polyethylene

- LDPE – Low Density Polyethylene

- LLDPE – Linear Low Density Polyethylene

- mLLDPE – Metallocene Linear Low Density Polyethylene

- PE copolymers

Application

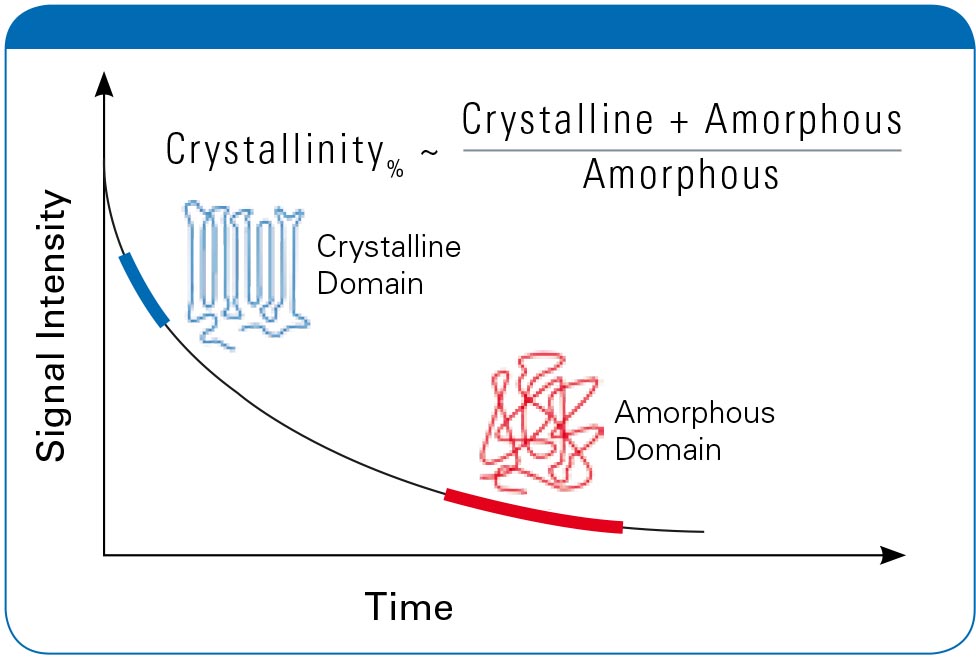

The application Crystallinity of PE is based on the different relaxation times in the crystalline and amorphous domains of the polymer. Protons in crystalline or rigid\ domains return significantly faster to the equilibrium state than protons in mobile domains. Measuring the decay signal at two characteristic times provides a ratio which corresponds to the samples crystallinity.

Measurement

Calibration

- Calibration range: 17 – 96 % crystallinity / 853 – 998 kg/m3

- Typical correlation factors above 0.990

- Typical mean standard deviation below 0.25 % (3.77 kg/m3)

- Typical mean standard deviation of repeated measurements below 0.04 % (0.604 kg/m3)

The method is calibrated with 3 to 5 samples of known crystallinity. NMR values (ratios) are related to crystallinity and/or density by linear regression Bruker-certified standard samples are provided for back-up calibration.

Recommended Equipment

- minispec mq one Polymer Analyzer for routine measurements

- minispec mq20 series for R&D and routine measurements

- Tempering block

- Automation (optional)

Beyond Quality Control

- minispec mq20 for in-depth PE research

- up to + 200°C

- T1 and T2 relaxation time measurements

- NMR signal fitting routine

Credit: Bruker

Contact us

388/5 Nuanchan Road, Nuanchan,

Buengkum, Bangkok 10230

0 2363 8585 (auto)

0 2363 8595

081 498 9939