Knowledge

Spectroscopic Solutions for the Biodiesel Industry

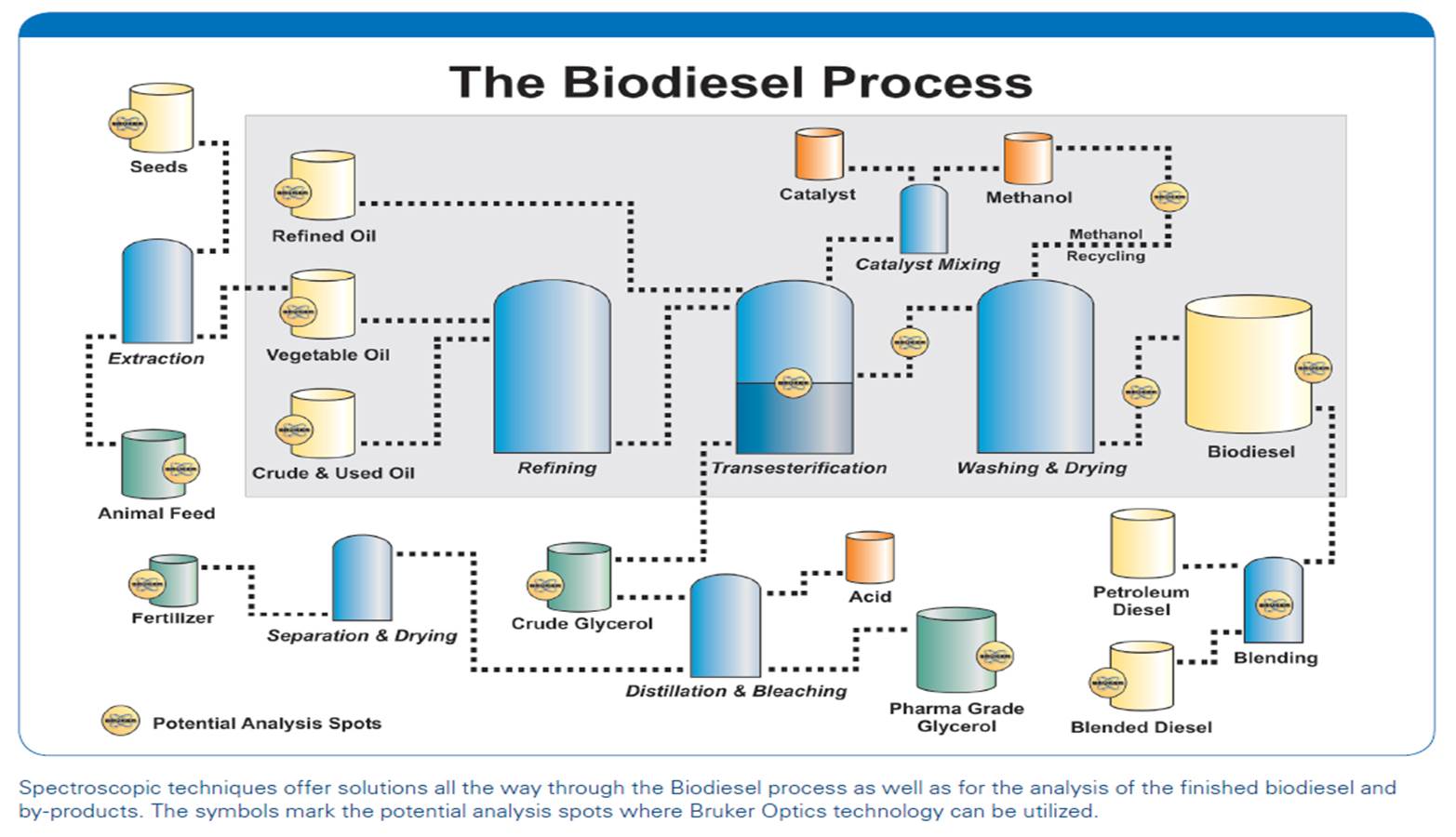

Bruker Optics offers an array like FT-IR, FT-NIR and TD-NMR to test the different stages of the biodiesel production

Spectroscopic Solutions for the Biodiesel Industry

Biodiesel is the fuel for the future. Soaring oil prices have encouraged the consumers worldwide to increase their use of biofuels made from natural resources. As an eco-friendly alternative to traditional petroleum diesel, it produces less air pollution, comes from renewable sources, is biodegradable and therefore safer for the environment. It can be blended in any ratio to conventional diesel, from additive levels to 100 percent biodiesel without compromise on quality and loss in engine performance. With biodiesel, any diesel engine can become a renewable fuel engine.

Bruker Optics offers an array of spectroscopic solutions like FT-IR, FT-NIR and TD-NMR to test the different stages of the biodiesel production, from the raw materials to transesterification and final blending. The rapid, non-destructive testing throughout the process leads to less down-time and improved quality, saving you time and money.

Analyzing incoming raw materials

A variety of feedstock sources such as vegetable oil, recycled cooking oils or animal fats can be converted into biodiesel. The yield of biodiesel from plantoil is however very much dependent on the quality of the incoming goods. If the raw materials contain for example higher concentration of free fatty acids (FFA), moisture, and phosphatides, the esterification process could become troublesome if those interfering components are not removed beforehand. Here, spectroscopy is a fast and accurate method to determine identity and exact composition of the incoming raw materials - of the oils and fats as well as of grains and seeds, if the crushing process is carried out in-house.

Monitoring the transesterification reaction

Biodiesel is composed of methylesters, which are formed during the reaction of triglycerides with a methanol/katalyst mix. By closely following up the concentrations of the reagents and products, process operators can determine and influence the efficiency and cost-effectiveness of the reaction. On-line spectroscopy can provide this valuable information, automatically and 24/7. Bruker Optics offers also solutions for the methanol recycling process.

Quality control & blend verification

Fuel-grade biodiesel must be produced to strict industry specifications (ASTM D6751, EN14214) in order to insure proper engine performance and avoid problems including clogging of fuel lines, injection systems and filters. Smallest quality deviations, like excess levels of glycerine can lead to costly claims for compensation.

Infrared instrumentation from Bruker Optics provides fast and accurate results with no sample preparation. It is so simple that these tests can be carried out even by unskilled personnel at the click of a button, without the need for costly training.

Biodiesel is designed for complete compatibility with petroleum diesel and can be blended in any ratio, from additive levels to 100 percent biodiesel. However, some vehicle manufacturers limit the use of biodiesel proportion in their engines and therefore a close control of the blends is compulsory. Spectroscopy can evaluate all blends, from B1 to B100 to high precision.

Testing the valuable by-products

The appealing aspect of the biodiesel process is that all by-products can be used, nothing is wasted. The economic advantages of selling glycerine, fertilizer and animal feed are enormous - if the quality is proven. Bruker Optics offers precalibrated systems for selected by-products of the biodiesel process.

Credit : Bruker Co., Ltd.

Contact us

388/5 Nuanchan Road, Nuanchan,

Buengkum, Bangkok 10230

0 2363 8585 (auto)

0 2363 8595

081 498 9939