Knowledge

Analysis of micro samples using FT-IR microscope

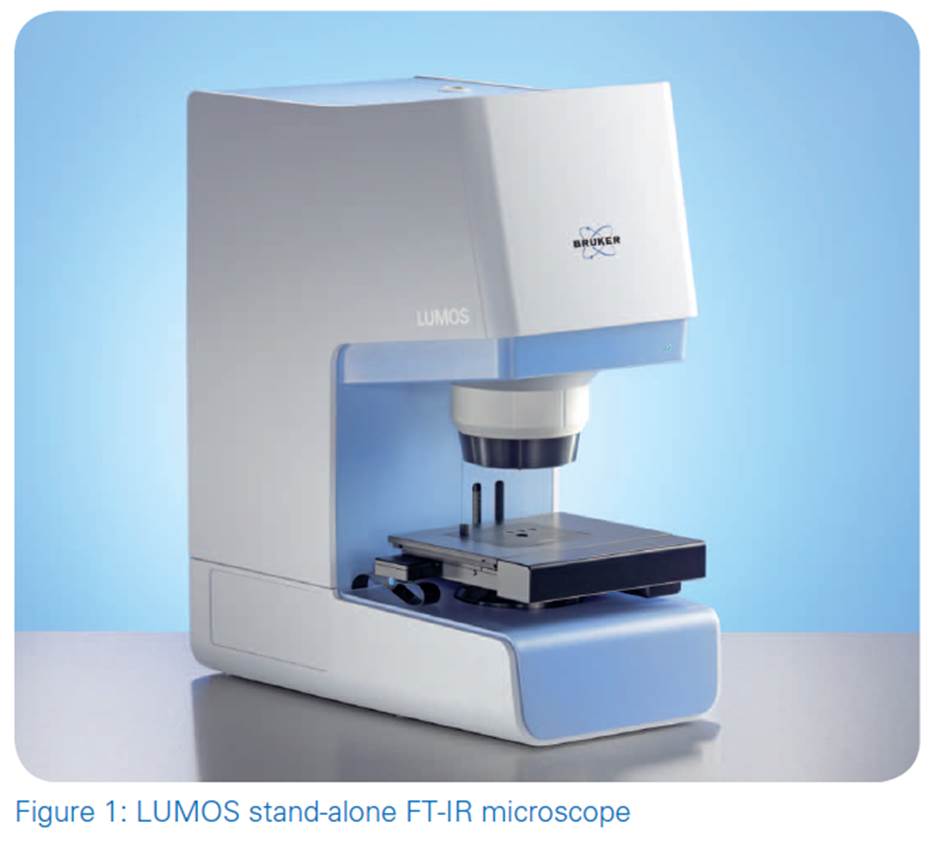

LUMOS FT-IR microscope is a compact and fully motorized stand-alone FT-IR microscope with a low cost of ownership

Analysis of micro samples

using the stand-alone FT-IR microscope LUMOS

Introduction

Fourier-Transform-Infrared (FT-IR) microscopy is a wellestablished method for the analysis of samples that are too small or complex to be measured in a standard IRspectrometer. With FT-IR microscopy it is possible to obtain an IR-spectrum anywhere on the sample with a very high local resolution and thereby revealing the chemical composition of an extremely defined part of the sample. Therefore this technique is a useful tool for quality control, forensic and biomedical applications to name only a few. Since it is possible to analyze a large variety of different samples like fibers, paint chips, contaminations or composite materials (e.g. laminates, tablets) there are numerous possible applications. For instance it is of interest to determine the chemical composition of different layers in a packaging material and to identify particles found on an electronic component or impurities localized in a rubber material.

So far most of the commercially available FT-IR microscopes are rather bulky and need an additional FT-IR spectrometer. Furthermore they are quite complex to use and require a high level of skill. With the new FT-IR microscope LUMOS Bruker offers a fully automated stand-alone solution that is very easy to use and requires little lab space. The OPUS software is a powerful but comfortable tool as well for the measurement procedure as for evaluation and visualization of the resulting data.

Instrumentation

The FT-IR microscope LUMOS is an all in one solution with an integrated spectrometer, a high degree auf motorization and a dedicated user-interface. It is utilizing state-of-theart optics for optimal sample visualization and infrared data collection. Its 8x objective provides the measurement impurimodes ATR, transmission and reflection and high quality visual inspection capabilities. The innovative motorized Attenuated Total Reflectance (ATR) crystal allows performing the complete measurement procedure fully automated including background and sample measurements. To provide perfect contact to samples ranging from soft to very hard the ATR-device offers three pressure steps and is equipped with a precise internal pressure control. The built in PermaVac Mercury-Cadmium-Telluride Detector (MCT) ensures a maintenance free operation and lownoise spectra. A high working distance and a comfortable field of view of 1.5 x 1.2 mm are facilitating the sample inspection. In combination with a motorized stage, fully automated mappings can be performed. Additionally for maximum performance and convenience the LUMOS includes amongst others:

A motorized ATR crystal, motorized transparent knife edge apertures and condenser

Automatic change of numerical aperture between IR and VIS

Two LED sources for transmission and reflection

A CCD camera with 4x digital zoom

Electronic recognition of sample plates

Optionally a motorized stage with a position accuracy of 0.1 μm

Optional macro accessory that allows to use all Quick Snap sampling

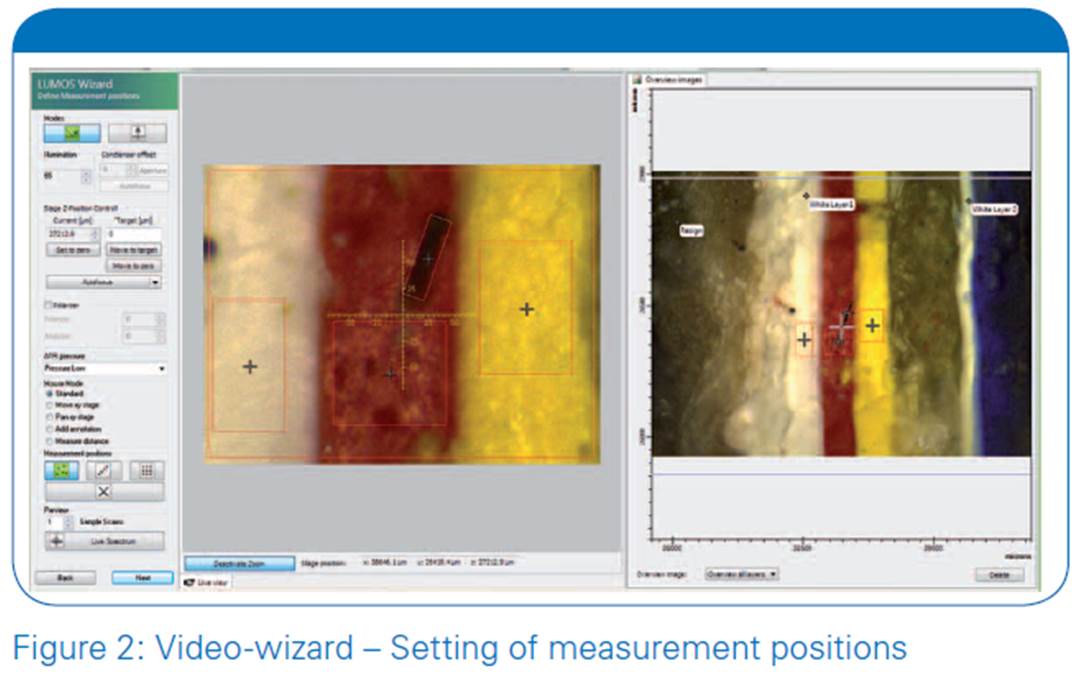

The user is guided through the whole measurement procedure by the dedicated OPUS Video-wizard, a user interface that always provides the appropriate functions for the current measurement step. Figure 2 shows the function bar on the left side during the setup of the measurement positions; with the Back button it is always possible to alter previous settings at will.

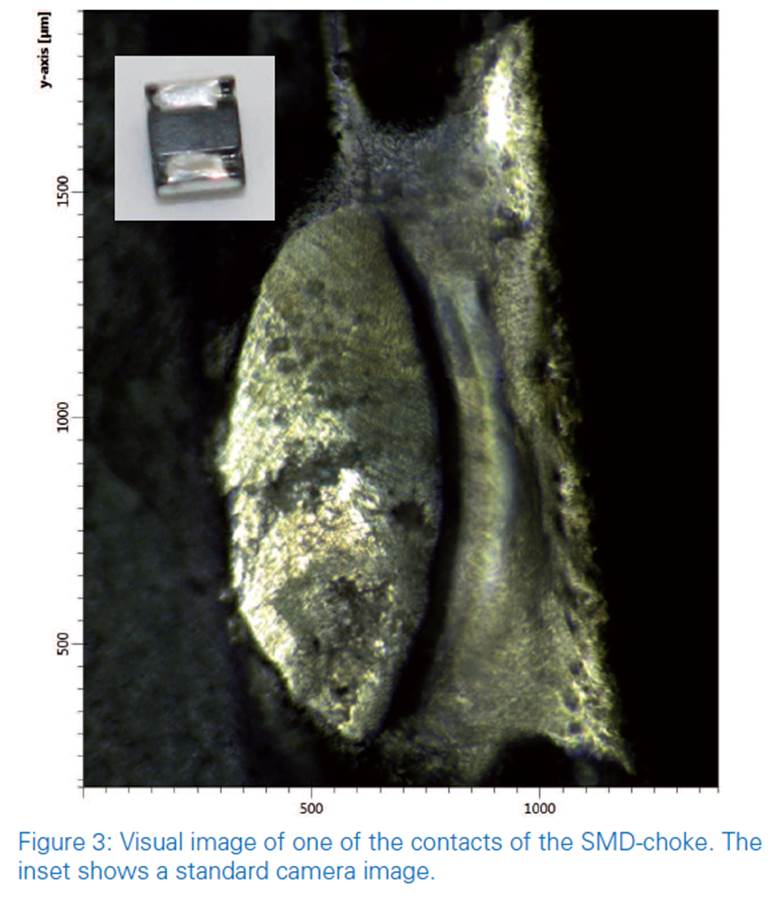

Application example: Identification of a contamination on a SMD choke

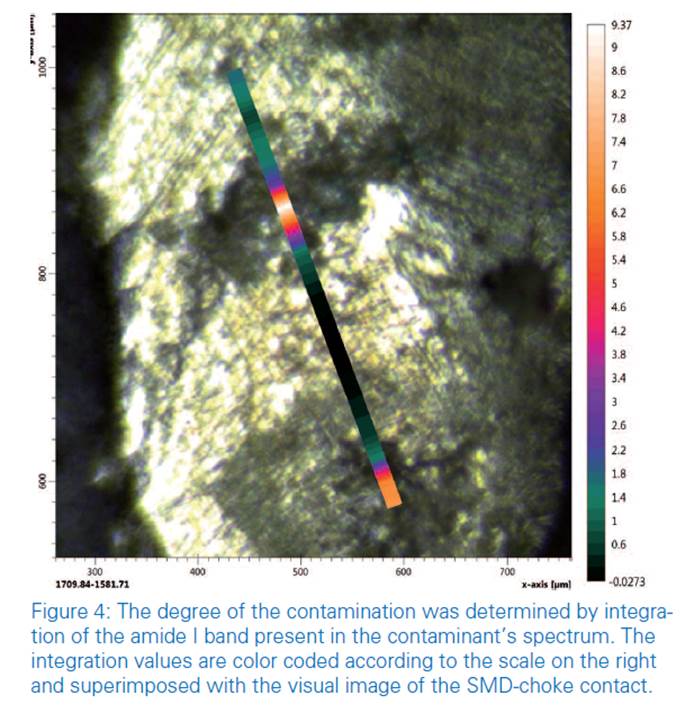

Contaminations have a negative impact on the product quality; especially in the field of microelectronics impurities are an important topic. Since electronic devices are getting smaller and smaller they are also becoming more and more vulnerable to all kinds of contaminations: A surface mounted device (SMD) which is contaminated can eventually not be soldered anymore and is a potential source of leak currents. In a more complex electronic element even a small grain of dust can have dramatic effects; most probably the element will not work at all. In order to eliminate the source of the contamination it is vital to know its chemical nature. Using FT-IR microscopy contaminations in the low micrometer range can be identified. As an example we show the analysis of a contamination on the soldering contact of a SMD-choke (see figure 4). The choke has a footprint of about 3.0 x 2.5 mm and a height of ca. 2 mm. Upon inspection with the visible objective of the LUMOS a series of black spots is visible on one of the contacts.

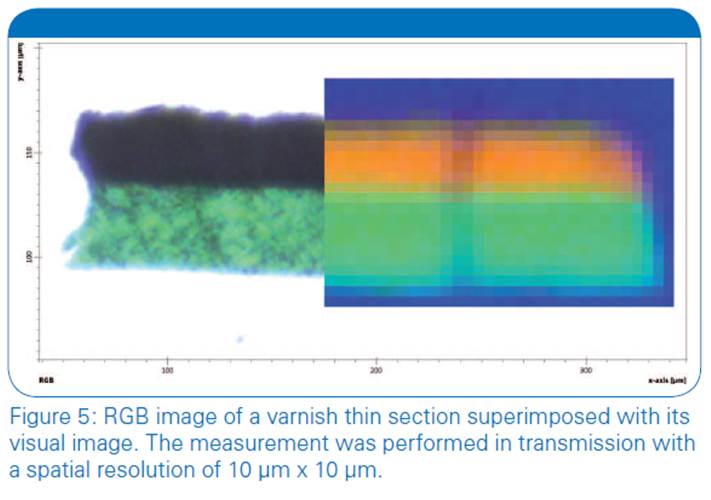

Application example: Transmission mapping measurement of a two layer varnish

As a second example we present the analysis of a twolayered varnish. For the measurement the sample was embedded in a resin, cut using a microtome and polished. A visual image was taken and the sample was analyzed in transmission mode by a so called mapping where a grid of subsequent spectra is acquired automatically. The IR-mapping was performed with a spatial resolution of 10 μm x 10 μm using an acquisition time of about 6 seconds (12 scans) per measurement position at a spectral resolution of 4 cm-1.

In figure 5 the “chemical image” of the varnish is shown superimposed with its VIS-image. Calculated as RGB image it shows the relative quantities of three sample components at each pixel, with each component being represented by one color. The chemical image clearly reveals the different chemical nature of the layers with a high spatial resolution and nicely matches with the visual image.

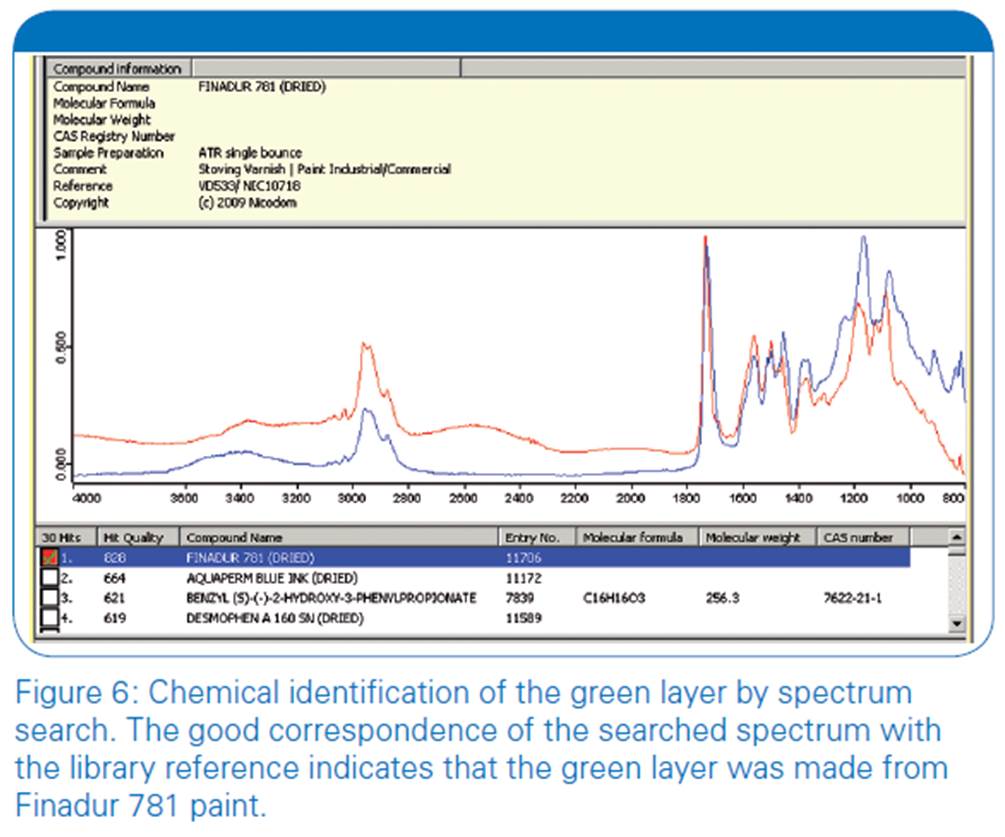

Additionally both varnish layers can be identified by searching individual spectra from any pixel of the chemical image in a spectra library. As an example figure 6 shows the search result for a typical spectrum in the green layer indicating it to be made from the specific paint Finadur 781.

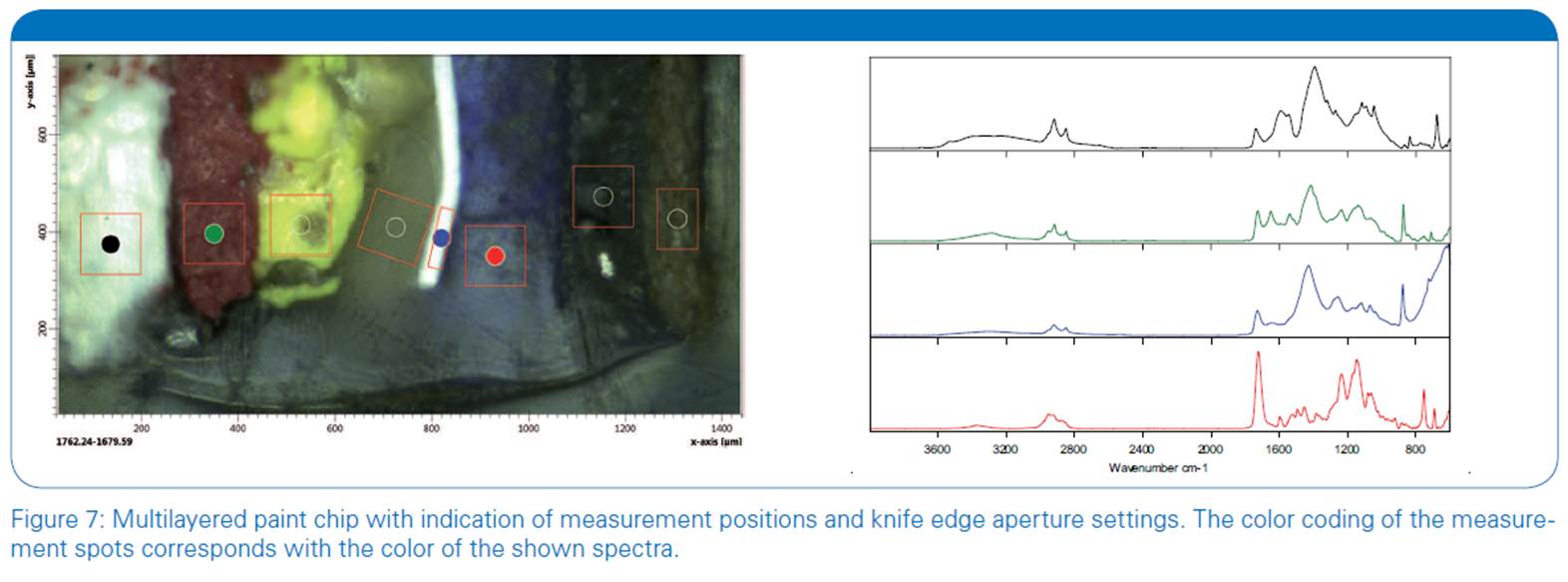

Application example: ATR measurement of a paint chip

As a third example the chemical composition of the multiple layers of a paint chip was to be analyzed. The material being too soft to allow preparation of a thin section the measurement was performed in ATR-mode. Here the measurement positions and the automated knife edge apertures were set individually for each layer. 32 scans per measurement at a spectral resolution of 4 cm-1 were used resulting in a measurement time of about 16 seconds per position. During the infrared analysis, the sample is brought into contact with the tip of the Germanium (Ge) ATR-crystal (100 μm in diameter) on all predefined measurement positions.

Figure 7 shows the overview image with the corresponding spectra of four layers of the paint chip. The color coding of the measurement spots is according to the shown spectra. All layers, including the two white layers can be clearly distinguished by means of their spectra.

The LUMOS is capable of performing ATR-mapping measurements fully automated. Due to its motorized ATR crystal and its motorized knife edge aperture the spot size can even be modified within the experiment. This is often required for laminates to match the field of view with the specifc structure of the sample.

Application Example: Mapping of a biological sample

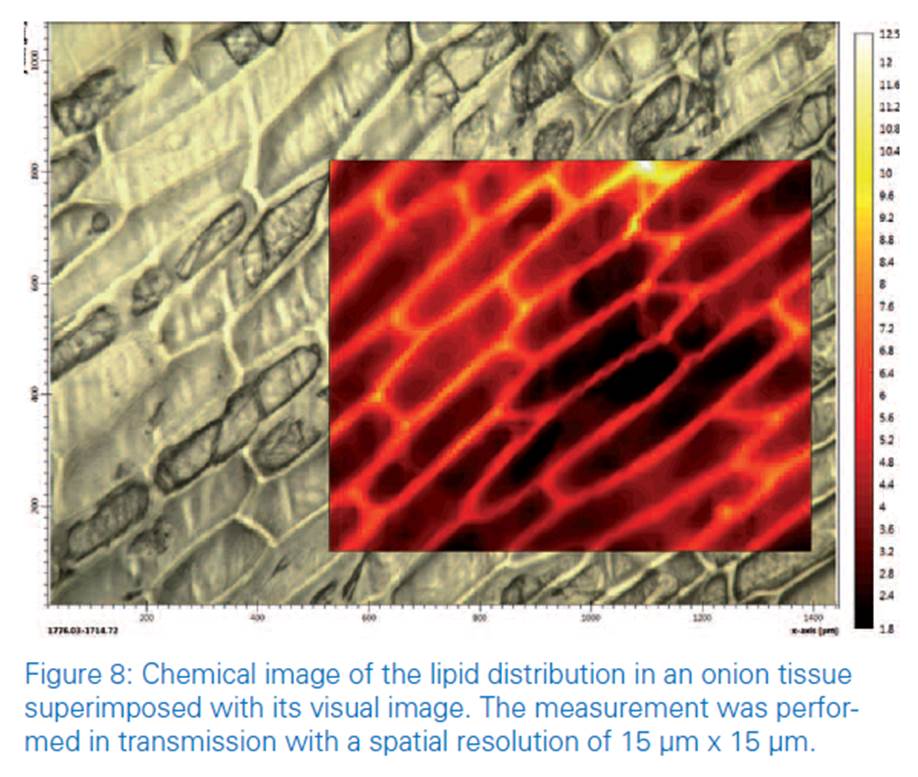

Chemical imaging using IR-microscopy is an established technique for the investigation of samples with complex chemical structures. Our demonstration-sample is a small piece of an onion tissue which was mapped in transmission mode. The chemical image consists of 58x47 measurement points and was recorded with an acquisition time of 1.5 seconds / position with a resolution of 15 x 15 μm and a spectral resolution of 8 cm-1. Figure 8 shows the chemical image superimposed with the visual image. Both images match perfectly and the single cells are clearly visible. The color coding of the chemical image shows the intensity of the lipid band around 1740 cm-1 and therefore the distribution of the lipids in the cells. As expected, the highest lipid concentration can be found in the cell walls since they contain a lipid bilayer.

Summary

The new LUMOS FT-IR microscope is a compact and fully motorized stand-alone FT-IR microscope with a low cost of ownership. Its dedicated software guides the user through the microscopic analysis step-by-step allowing even inexperienced users to operate the system. The fully automated procedure of both sample and background measurements for all measurement modes including ATR saves precious working time.

The LUMOS provides high quality data as well in visualization as in IR-analysis even at high spatial resolution thereby opening a wide range of possible applications. The identification of tiny particles or contaminations allows finding the reason for product failures. In forensics the analysis of fibers and varnish pieces can provide a piece of evidence. The chemical composition of inhomogeneous structures like multilayer polymers, paintings or biological tissues can be visualized applying the mapping approach. Its high comfort in use and its applicational versatility make the LUMOS a perfect instrument for the daily IR-microscopic routine. Though, due to its outstanding performance it is even suitable for demanding research applications.

Credit : Bruker Co., Ltd.

Contact us

388/5 Nuanchan Road, Nuanchan,

Buengkum, Bangkok 10230

0 2363 8585 (auto)

0 2363 8595

081 498 9939