Knowledge

Quality Control in Cement Production

The solution CEMENT-QUANT therefore offers well selected certified reference materials and guarantees accurate results

Reliable Process and Quality Control

in Cement Production by EDXRF (ASTM C114)

Introduction

These days cement is produced in a highly optimized, continuous process. In order to maintain a constant product quality, each of the various production steps must be carefully controlled. This requires the analysis of relevant elements in raw materials, intermediate process products and the final product. Some elements, such as silicon and calcium, are present in higher concentrations, whereas others, such as iron and sulfur, are present in minor concentrations. In addition to these, there is an increasing demand for the determination of lighter elements such as sodium and magnesium which places further demands on the analytical system specification. For such multi-element analysis in process and quality control, the energy dispersive X-ray fluorescence (EDXRF) spectrometer S2 RANGER is well suited as monitoring system.

The precision and long-term stability of the system is demonstrated by measurements in accordance to norm ASTM C114. In order to prove the instrument stability, different samples were measured over a period of 30 hours.

Instrument

The measurements were performed on an S2 RANGER with XFlash® LE silicon drift detector (SDD). The system is an all-in-one benchtop system with TouchControlTM, an easy-to-use touchscreen interface (see figure 1).

This XFlash® LE silicon drift detector is equipped with an ultrathin, high transmission entrance window which considerably enhances the sensitivity for light elements. In order to obtain optimum results, an Ag target X-ray tube was used instead of the standard Pd target X-ray tube. Figure 2 shows a typical spectrum of a cement sample obtained with the Ag X-ray tube. The spectrum indicates the clearly separated Na signal at 1.040 keV. CEMENT-QUANT for S2 RANGER was used to setup the calibration by using the optimal measurement conditions.

Results

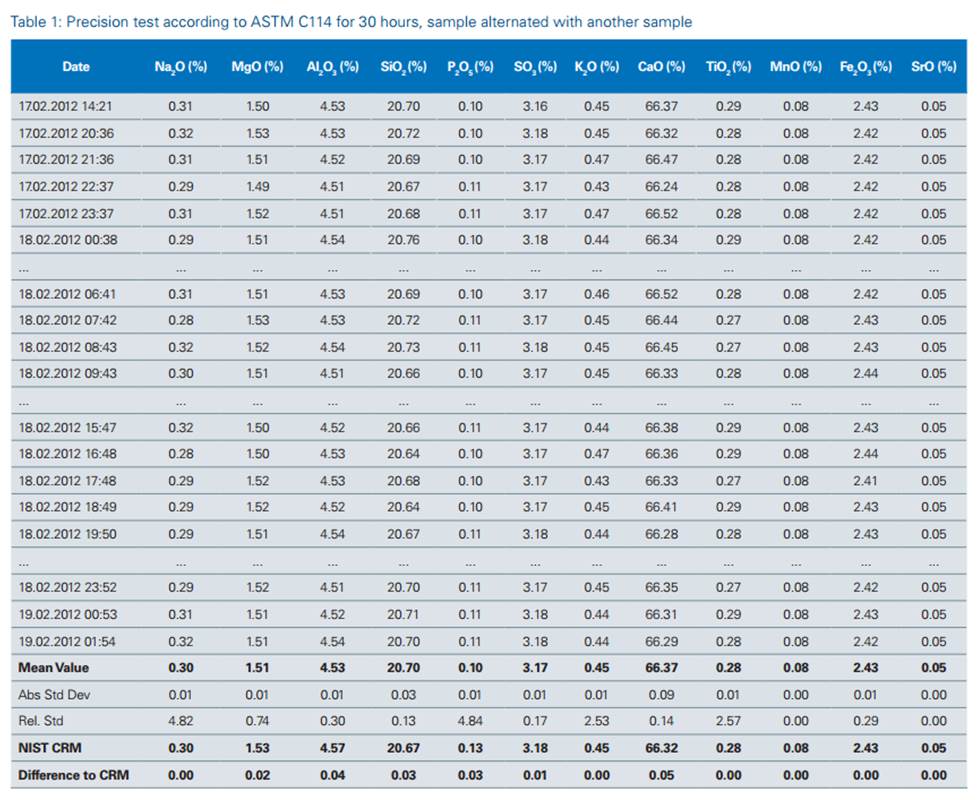

Measurements to prove precision and long-term stability were performed in accordance with ASTM C114. The norm defines the maximum permissible variations from the certified values for each element. In order to prove the stability, two different fused bead samples were analyzed over a period of 30 hours. No intermediate drift correction was performed during these 30 hours. Typical precision data for a cement sample are shown in table 1.

The results shown in table 1 prove the excellent repeatability and reproducibility of the S2 RANGER. The measured concentrations are in excellent agreement with the certified concentrations of the materials.

The precision data for another sample is shown as process control charts over a period of 30 hours in figures 6 to 8 (for SiO2, MgO and Na2O, respectively).

Conclusions

The data shown demonstrate the excellent performance of the S2 RANGER with XFlash® LE silicon drift detector and Ag target tube. Due to the ultrathin, high transmission window of the detector and the chosen anode material, low ppm levels of light elements can be accurately determined. The results also verify the good precision and long-term stability in accordance with ASTM C114. The solution CEMENT-QUANT therefore offers well selected certified reference materials and guarantees accurate results with minimum set-up time.

All in all, the suitability of the S2 RANGER as a monitoring system for process and quality control in modern cement plants is demonstrated.

Credit : Bruker Co., Ltd.

Contact us

388/5 Nuanchan Road, Nuanchan,

Buengkum, Bangkok 10230

0 2363 8585 (auto)

0 2363 8595

081 498 9939