Knowledge

Determination of Low Sulphur in Petroleum

The S2 RANGER’s analytical precision and accuracy satisfy all demands for reliable quality and process control

Determination of Low Sulphur

in Automotive Fuels and Petroleum Products

This report describes the analytical precision of the S2 RANGER with XFlash® for low sulphur detection in automotive fuels and other petroleum products exceeding the actual international standards for EDXRF.

Introduction

Sulphur is present in crude oil in concentrations up to about 5% by weight. It is therefore commonly found in derivative petroleum products from the % levels in lubricating oils down to trace levels in automotive fuels.

Sulphur concentrations in petrochemical products, like automotive fuels and lubricants, are of primary concern in the hydrocarbon processing industry. Harmful effects of sulphur on engine parts or machines and hazardous air pollution caused by sulphur oxides are driving regulations that require the reduction and accurate reporting of sulphur content. It has therefore become essential that sulphur concentrations be closely monitored and controlled in all petrochemical products.

In the refining process, sulphur concentrations are reduced from several percent in crude oil to low ppm levels in gasoline. This reduction requires close process control. To ensure and control petroleum product quality, sulphur analysis is also critical along the supply chain at pipelines, tank farms and customs.

Today energy-dispersive X-ray fluorescence (EDXRF) spectrometry is well established for the analysis of sulphur, as well as additives and impurities, down to the trace level in products derived from petroleum. The development of silicon drifts detectors (SDDs), which provide very good spectral resolution at high count rates and low cost of ownership, has made EDXRF the method of choice at refineries and chemical plants worldwide. Analysis requirements are regulated in international standards like ASTM 4294 and DIN/EN 20847.

This report demonstrates the analytical performance of the S2 RANGER with XFlash® SDD technology for the determination of low sulphur concentrations in automotive fuels and other petroleum products. Measurement reproducibility and long term stability data are presented, showing how the S2 RANGER exceeds international standards for sulphur control.

Instrumentation

The S2 RANGER is distinguished from conventional EDXRF instruments by its innovative design. With direct sample excitation geometry and a maximum excitation power of 50 W, the S2 RANGER’s beam path results in high detection sensitivity for all elements. The SDD technology of the XFlash® detector offers excellent resolution, even at high input count rates. This combination of direct excitation beam path and high resolution leads to the outstanding analytical performance of the S2 RANGER.

The easy and intuitive touch screen operation of the S2 RANGER makes the instrument especially useful in industrial settings. The Touch Control™ interface is easy to learn and failsafe to operate even for new or inexperiencedusers.

Sample Preparation

System calibration was performed using eight standards prepared with blank iso-octane and di-n-buthyl sulphide covering the concentration range from 0 to 0.1%. The calibration range of ASTM 4294/DIN EN ISO 20847 was expanded with two additional standards of 5 and 10 ppm.

For the measurements, 5 g of the sample or standard were poured into a liquid cup with 5 µm polycarbonate film support.

Measurement Parameters

The measurements were performed on the S2 RANGER with XFlash detector using Pd La1 excitation at 10 kV and 2000 µA in a helium atmosphere. The total measurement time was 300 s.

Results

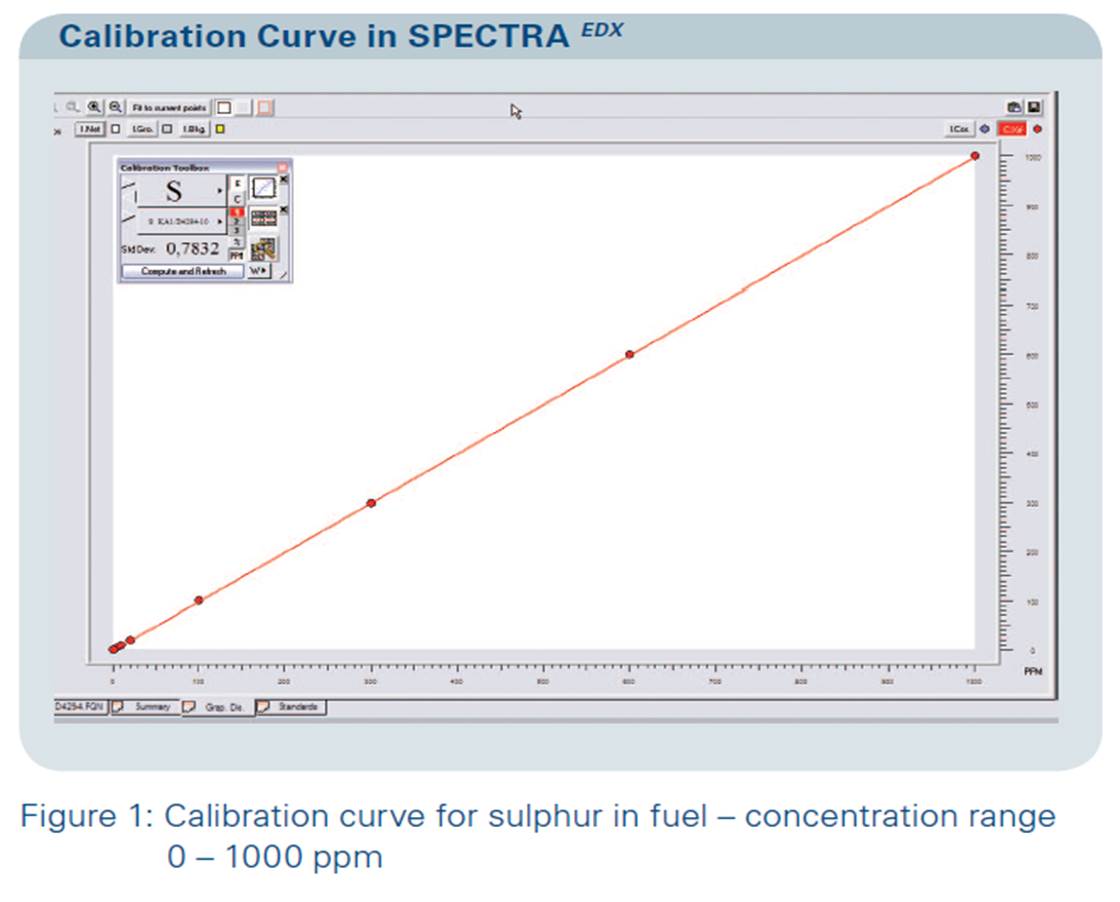

The calibration curve was calculated from the intensity of the standard samples with multiple regression. The absolute standard deviation of the calibration was 0.78 ppm, indicating very good correlation between certified and measured concentrations of the standards. With less than 1 ppm absolute deviation, the calibration was suitable for the reliable analysis of sulphur concentrations down to about 10 ppm. The calibration curve is shown in Figure 1.

The detection limit for sulphur in fuel samples is 1 ppm (3, 300s).

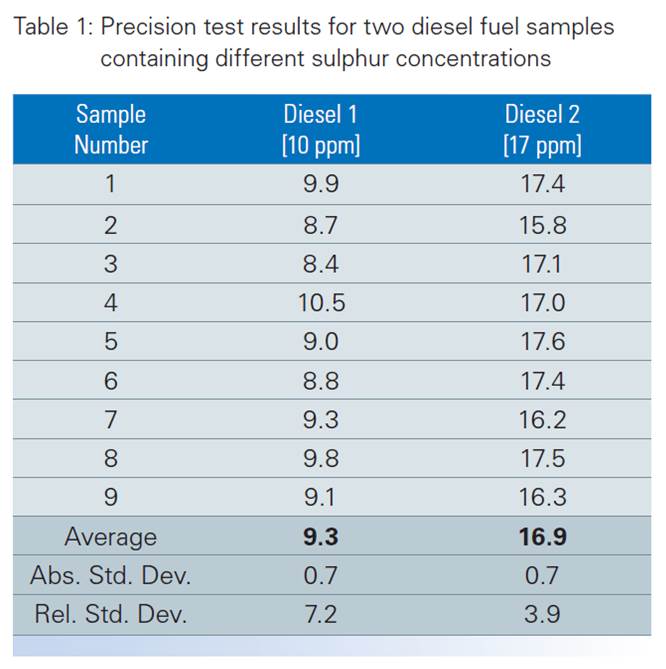

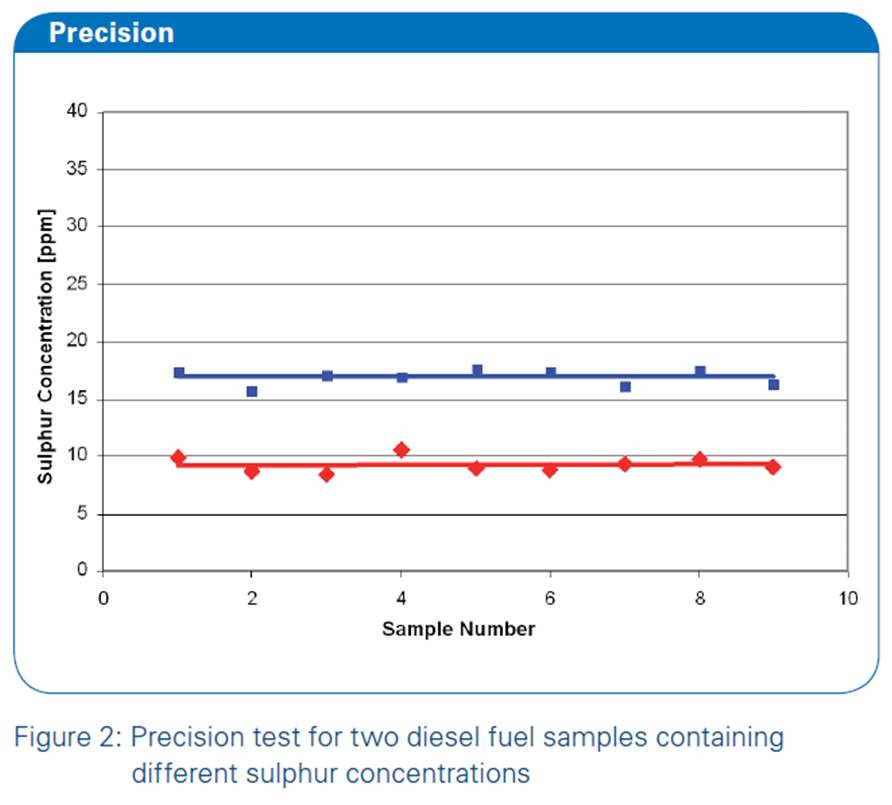

The analytical precision was tested with two diesel fuel samples: sample one with a concentration of 10 ppm and sample two with 17 ppm sulphur. The results of the test are shown in Table 1 and Figure 2.

Conclusions

These results clearly demonstrate that the S2 RANGER exceeds the actual international standards for low sulphur analysis with EDXRF. The concentration range of sulphur analysis in automotive fuels according to ASTM 4294 is 0.015 – 5 %. The calibration data achieved a sulphur detection limit of 1 ppm. The analytical precisions shown at two very low sulphur concentrations are proof of the high analytical performance of the S2 RANGER with XFlash® detector.

The S2 RANGER’s analytical precision and accuracy satisfy all demands for reliable quality and process control. The instrument’s flexibility for other analytical tasks, such as the determination of additives in lubricants or residual catalysts, in combination with its easy, intuitive TouchControl™ make the S2 RANGER the instrument of choice for the petrochemical industry.

Credit : Bruker Co., Ltd.

Contact us

388/5 Nuanchan Road, Nuanchan,

Buengkum, Bangkok 10230

0 2363 8585 (auto)

0 2363 8595

081 498 9939