Advance Analytical

เครื่องมือวิเคราะห์ทางวิทยาศาสตร์ขั้นสูง Advance Analytical

Advance Analytical

Hits: 3070

the minispec mq series TD-NMR Analyzers

Versatile Time-Domain NMR Analyzer from the NMR Experts.

- Relaxation and diffusion analysis

- Rapid, non-destructive, solvent free technology

- No sample preparation

- Replaces wet chemical and physical tests

- Simple linear calibration with 3 or more samples

- Chemometric calibration option

- 21 CFR part 11, IQ/OQ/PQ and GLP compliance

- Low maintenance Sample temperature range from -100°C to +200°C for unique R&D applications

- Fully developed magnet design for utmost speed of analysis

TD-NMR General Principles

TD-NMR uses a permanent magnetic field and radio frequency (RF) energy to look at NMR sensitive nuclei such as hydrogen and fluorine. In response, RF signals are generated by the sensitive nuclei and the signals are detected by the minispec. The amplitude and duration of these signals are related to the properties of the sample.

Unlike other spectroscopic techniques, TD-NMR is unaffected by sample color and surface properties. The minispec is perfectly suited to both QA/QC labs and R&D facilities because it is a nondestructive and non-invasive measurement that requires no sample preparation.

Unlike other spectroscopic techniques, TD-NMR is unaffected by sample color and surface properties. The minispec is perfectly suited to both QA/QC labs and R&D facilities because it is a nondestructive and non-invasive measurement that requires no sample preparation.

the minispec International Standard Methods

There are several published and well established methods for the minispec, including a number of international standard methods. In the food industry, Solid Fat Content (SFC) measurements are described in official methods by several organizations, including ISO, IUPAC and AOCS. In agriculture, oil and moisture in oilseeds and residues is determined by international standard methods. In the petrochemical industry, percent hydrogen in hydrocarbons like jet fuel and diesel are the subject of ASTM methods.

Food Industry

- Solid Fat Content in fat compositions (AOCS Cd 16b-93, ISO 8292 & IUPAC 2.150 methods)

- Oil and moisture in seeds and oilseed residues (AOCS Ak4-95, ISO 10565 & 10632 methods, USDA GIPSA approved)

- Solid Fat Content as well as total fat content in chocolate and chocolate related products

- Droplet size analysis in O/W and W/O emulsions Oil, water and protein in dry and wet food and feed

Textile Industry

- Spin Finish on Fibres (OPU)

- Coatings on Polymers

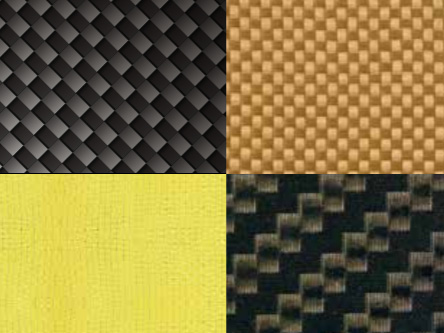

Polymer Industry

- Xylene soluble content in polypropylene

- Density and crystallinity in polyethylene

- Rubber content in polymers like ABS or polystyrene

- Cross-link density of elastomers

Petrochemical Industry

- Hydrogen content in hydrocarbons (ASTM D 7171 method)

- Oil content in paraffin and wax

Pharmaceutical Industry

- Fat and lean in live mice and rats

- Contactless weight determination

- Moisture and solvents in powders and tablets

- Contrast agent investigations near MRI fields: 0.25 T, 0.5 T, 0.75 T, 1.0 T and 1.5 T

Healthcare Industry

- Fluorine content in toothpaste

- Melting properties of cosmetics

R&D and Academics

- All types of temperature dependent relaxation time studies

- Diffusion experiments

- Single-Sided NMR

Typical minispec Configurations

- mq60: 1.41 T / 60 MHz

- mq40: 0.94 T / 40 MHz

- mq20: 0.47 T / 20 MHz

- mq10: 0.23 T / 10 MHz

- mq7.5: 0.17 T / 7.5 MHz

Solid Fat Content (SFC) Analysis

Solid Fat Content (SFC) determination is of prime importance for food processing and development. Raw materials like fat compositions or blends need to be characterized and controlled according to their

melting profiles.

Xylene Soluble Content in Polypropylene

The term ‘Xylene Solubles’ refers to the percentage of soluble species in homo- and copolymers of polypropylene. Its value correlates to the R21 value and to the amorphous content of the polymer.

Crystallinity & Density of Polyethylene

The crystallinity of polyethylene (PE) determines the stiffness, the impact and tensile strength, the permeability and the resistance of the material.

Spin Finish on Fibers Oil Pick Up with Sample Weighing

Spin Finish is added to fibers to improve their downstream handling in the process of manufacturing.

Textile Check for Spin Finish Removal

The minispec is able to detect Spin Finish down to very low concentrations. Thus, it is the method of choice to monitor the washing of Spin Finish on fibers and control the absence of Spin Finish.

Dip on Fibers Elastomer Coating on Fibers

For special fiber applications, an elastomer coating, so-called dip, is necessary to improve the fiber’s properties such as wind stopping, water repellent, and reinforcement.

Food & Feed Industry Fast and Reliable Quality Control by Time Domain NMR

To determine the essential properties of food and feed, Bruker developed a powerful device for fast

and reliable answers throughout all production and processing steps: the minispec based on Time

Domain (TD)-NMR.

the minispec QC and R&D in the Chocolate Field

For many years the Bruker minispec has been well-known in the Fat and Chocolate industries for a precise and reliable determination of fat melting profiles on basis of the Solid Fat Content (SFC) Determination.

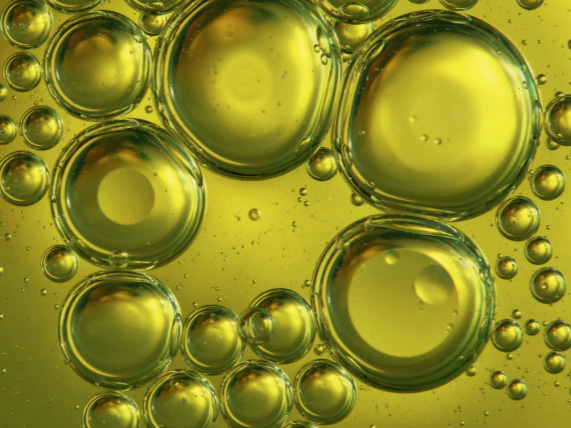

Droplet Size Distribution in Food Emulsions

The droplet size distribution in these emulsions influences their taste, smell, and appearance, as well as their shelf life and spread behavior.

Oil & Moisture in Seeds and Nuts

The minispec benchtop Time Domain NMR (TD-NMR) analyzer is a proven performer for measurement of oil and moisture in oilseeds, residues and nuts.

Fluorine in toothpaste

With Time Domain Nuclear Magnetic Resonance (TD-NMR), the fluorine content can be accurately

measured irrespective of the fluorine compound and the toothpaste matrix.

Hydrogen Content in Hydrocarbons

TD-NMR analysis of hydrogen content in hydrocarbons, like diesel or jet fuel.

Contact us

Syntech Innovation Co., Ltd.

388/5 Nuanchan Road, Nuanchan,

Buengkum, Bangkok 10230

388/5 Nuanchan Road, Nuanchan,

Buengkum, Bangkok 10230

0 2363 8585 (auto)

0 2363 8595

081 498 9939

3089213

Today

Yesterday

This Month

All days

171

1549

28921

3089213

Your IP: 216.73.216.80

2026-02-17 02:26