Knowledge

Used Lubricating Oil Analysis by FT-IR

Standard Practice for Condition Monitoring of Used Lubricants by Trend Analysis Using FT-IR Spectrometry

Used Lubricating Oil Analysis by FT-IR

Infrared (IR) spectroscopy can be used for the routine monitoring of degradation by-products, contaminants and additive levels in used bricatinglu oils. Acceptance of this technique as a standard method for the analysis of used oils and lubricants has been slow in coming for several reasons. The most notable hindrance is the fact, that much of the data used in assessing engine and lubricant performance have been historically obtained using traditional physical and wet chemical methods.

The lower cost of modern Fourier transform (FT-IR) systems, along with the ability to obtain higher quality data rapidly has made this technique attractive for routine analysis applications. As the need for obtaining quicker analysis resultsof for routine monitoring of in-service lubricants increases, spectroscopic techniques such as FT-IR will gradually replace various time-consuming and tedious traditional wet chemical and physical analysis methods. Recently, the ASTM has adopted a new standard practice E2412 entitled; “Standard Practice for Condition Monitoring of Used Lubricants by Trend Analysis Using Fourier Transform Infrared (FT-IR) Spectrometry” illustrating the increased application of FT-IR spectroscopy in this field.

Why are in-service lubricating oils tested?

In-service lubricating oils are tested to diagnose the lubricant’s condition in order to determine when there needs to be an oil change to avoid engine damage and prolong engine life. Engine oils provide lubrication of engines moving parts and protect them from wear and corrosion. In diesel engines, the oil must also suspend soot particles resulting from incomplete combustion of fuel. The composition of the lubricating oil can indicate whether there was improper combustion seal leakage or any changes in the base oil. The analysis of in-service oils also provides information about engine-related functions to identify component failures or harmful operating conditions.

Oil analysis by Fourier transform infrared spectroscopy

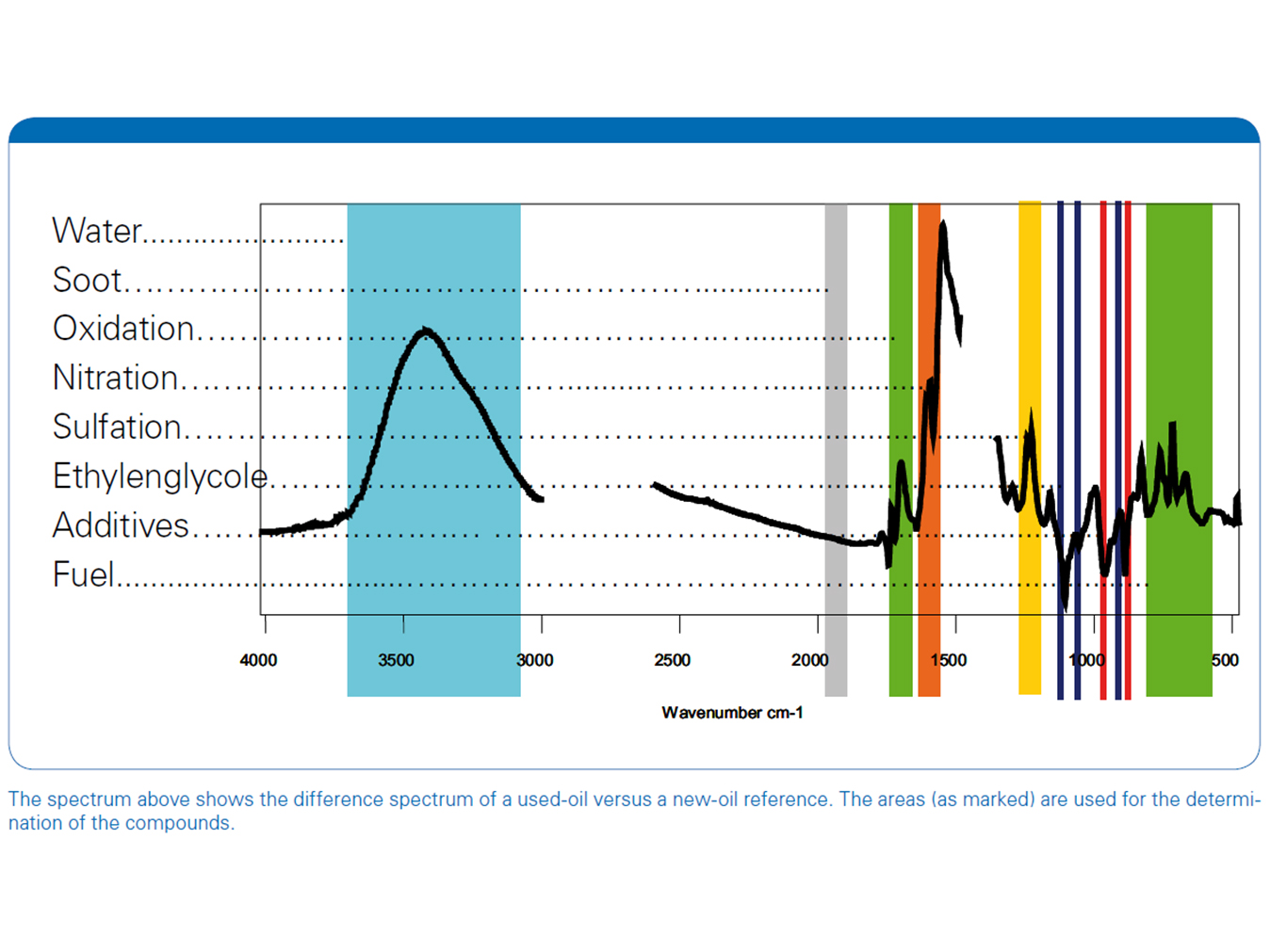

Used oil samples are complex mixtures of a large number of different compounds and include compounds derived from the original formulation of the base oil and its additives, oil degradation by-products and contaminants. The challenge of the analysis is to determine the small concentrations of degradation by-products and contaminants in the presence of the base oil and additives. In FT-IR spectroscopy, you can subtract out the spectrum of the base oil and additives from the used oil sample spectrum to obtain a differential spectrum and which represents only the changes in the oil. In that way, the changes in the oil due to accumulation of degradation by-products, additive depletion and contamination levels can be more readily visualized. Due to the the digital data handling of FT-IR spectrometers, the spectra of many reference oils simply samples can simply be stored to the hard disk and compared to their respective used oil sample analysis results at a later time. This allows for the condition of the lubricant to be trended at different sampling time points while it is in-service.

Credit : Bruker Co., Ltd.

Contact us

388/5 Nuanchan Road, Nuanchan,

Buengkum, Bangkok 10230

0 2363 8585 (auto)

0 2363 8595

081 498 9939