Hits: 9507

X-ray Analysis

Hits: 9507

Hits: 9507

X-ray Analysis

(เอกซ์เรย์ดิฟแฟรกชันและเอกซ์เรย์ฟลูออเรสเซนซ์)

Bruker designs and manufactures analytical instrumentation for elemental analysis, materials research, structural and surface investigations.

Bruker's range of technologies contains XRD, SAXS, SC-XRD, X-ray Micro-CT, XRF, Handheld XRF, Micro-XRF and TXRF, X-ray Metrology, EDS, WDS, EBSD, SEM Micro-XRF and SEM Micro-CT, OES, and CS/ONH-Analysis.

Our innovative solutions enable a wide range of customers in heavy industry, chemistry, pharmacy, ophthalmic, semiconductor, solar, life science, nanotechnology, and academic research to make technological advancements and to accelerate their progress.

Bruker's range of technologies contains XRD, SAXS, SC-XRD, X-ray Micro-CT, XRF, Handheld XRF, Micro-XRF and TXRF, X-ray Metrology, EDS, WDS, EBSD, SEM Micro-XRF and SEM Micro-CT, OES, and CS/ONH-Analysis.

Our innovative solutions enable a wide range of customers in heavy industry, chemistry, pharmacy, ophthalmic, semiconductor, solar, life science, nanotechnology, and academic research to make technological advancements and to accelerate their progress.

X-ray Diffraction (XRD)

(เครื่องวิเคราะห์การเลี้ยวเบนรังสีเอกซ์)

Materials property characterization from fundamental research to industrial quality control

Bruker's X-ray diffraction portfolio covers a wide range of X-ray scattering techniques for materials characterization and quality control of crystalline or non-crystalline materials such as powders, solid blocks, thin films or liquids.

Techniques include X-ray powder diffraction (XRPD), diffuse or "total" scattering (PDF analysis), small angle X-ray scattering (SAXS), thin-film analysis, and X-ray imaging. A unique platform design allows to configure each instrument for a wide range of applications.

Bruker's X-ray diffraction portfolio covers a wide range of X-ray scattering techniques for materials characterization and quality control of crystalline or non-crystalline materials such as powders, solid blocks, thin films or liquids.

Techniques include X-ray powder diffraction (XRPD), diffuse or "total" scattering (PDF analysis), small angle X-ray scattering (SAXS), thin-film analysis, and X-ray imaging. A unique platform design allows to configure each instrument for a wide range of applications.

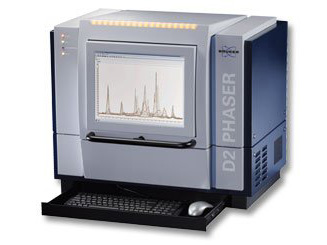

D2 PHASER X-ray Diffraction

The D2 PHASER is a novel desktop X-ray diffraction tool enabling the analysis of poly-crystalline material. The D2 PHASER desktop diffractometer is equipped with an integrated PC and a flat screen monitor. The new and very easy-to-use workflow software DIFFRAC.SUITE allows measurement and analysis right out of the box.

D2 PHASER – All-in-one crystalline phase analysis tool

The D2 PHASER is the most compact and fastest, all-in-one crystalline phase analysis tool available on the market. It is mobile and easy to install with only the need for standard electrical power. The D2 PHASER is therefore ideal for laboratory or on-location operation, in other words, it is a true Plug’n Analyze system.

Ease-of-use, high performance and low cost of ownership are the key features of the D2 PHASER desktop diffractometer. The D2 PHASER is the price/performance leader for X-ray powder diffraction in laboratories and QC/PC applications for e.g. cement, industrial minerals, geology, chemistry, pharmaceuticals, as well as for educational purposes.

Applications

D2 PHASER – All-in-one crystalline phase analysis tool

The D2 PHASER is the most compact and fastest, all-in-one crystalline phase analysis tool available on the market. It is mobile and easy to install with only the need for standard electrical power. The D2 PHASER is therefore ideal for laboratory or on-location operation, in other words, it is a true Plug’n Analyze system.

Ease-of-use, high performance and low cost of ownership are the key features of the D2 PHASER desktop diffractometer. The D2 PHASER is the price/performance leader for X-ray powder diffraction in laboratories and QC/PC applications for e.g. cement, industrial minerals, geology, chemistry, pharmaceuticals, as well as for educational purposes.

Applications

- Cement

- Minerals & Mining

- Material Properties

D8 ADVANCE X-ray Diffraction

The innovative design of the D8 ADVANCE with DAVINCI design plausibly combines operating safety, ease of use, and user safety. Well-matched hardware, electronics, and software ensure an easy adaptation to any application in the field of X-ray powder diffraction.

The new D8 ADVANCE ECO is the latest member of the comprehensive D8 XRD product family. It combines the proven high performance of the D8 series with easy extendability and upgradability.

DAVINCI Design

The intelligent beam path components of the D8 ADVANCE with DAVINCI design provide true plug’n play functionality requiring minimum or even no user intervention. Featuring automatic and tool-free switching of the diffraction geometry without the need for complex adjustments, the D8 ADVANCE with DAVINCI design broadens the analytical capabilities for a wide community of X-ray diffraction users.

Together with the ‘Best-Data-Guarantee’, which refers to the ‘Alignment Guarantee’ and ‘Detector Guarantee’ it just means: operating safety assured.

New software DIFFRAC.SUITE

The D8 ADVANCE with DAVINCI design comes with the new software DIFFRAC.SUITE. The plug’n play functionality is consistently implemented: any component mounted to the instrument registers itself with its relevant parameters. The DIFFRAC.SUITE offers intuitive operation and the graphical user interface can be customized to match the operator’s requirements, and last but not least, features the leading algorithms of its predecessor DIFFRACplus – ease of use assured.

Finally, the D8 ADVANCE with DAVINCI design complies with all the recent X-ray, machine, and electric safety directives of the EC, which is certified by various independent institutions. Thus running the D8 ADVANCE with DAVINCI design in universities, research institutes, R&D laboratories, quality control environments etc. means comprehensive user safety and minimum effort with the local authorities supplying the permission to operate the instrument.

The new D8 ADVANCE ECO is the latest member of the comprehensive D8 XRD product family. It combines the proven high performance of the D8 series with easy extendability and upgradability.

DAVINCI Design

The intelligent beam path components of the D8 ADVANCE with DAVINCI design provide true plug’n play functionality requiring minimum or even no user intervention. Featuring automatic and tool-free switching of the diffraction geometry without the need for complex adjustments, the D8 ADVANCE with DAVINCI design broadens the analytical capabilities for a wide community of X-ray diffraction users.

Together with the ‘Best-Data-Guarantee’, which refers to the ‘Alignment Guarantee’ and ‘Detector Guarantee’ it just means: operating safety assured.

New software DIFFRAC.SUITE

The D8 ADVANCE with DAVINCI design comes with the new software DIFFRAC.SUITE. The plug’n play functionality is consistently implemented: any component mounted to the instrument registers itself with its relevant parameters. The DIFFRAC.SUITE offers intuitive operation and the graphical user interface can be customized to match the operator’s requirements, and last but not least, features the leading algorithms of its predecessor DIFFRACplus – ease of use assured.

Finally, the D8 ADVANCE with DAVINCI design complies with all the recent X-ray, machine, and electric safety directives of the EC, which is certified by various independent institutions. Thus running the D8 ADVANCE with DAVINCI design in universities, research institutes, R&D laboratories, quality control environments etc. means comprehensive user safety and minimum effort with the local authorities supplying the permission to operate the instrument.

X-ray Fluorescence (XRF)

(เครื่องวิเคราะห์หาปริมาณธาตุด้วยรังสีเอ็กซ์)

Elemental Analysis, Process and Quality Control

X-ray fluorescence analysis (XRF) – one of the best analytical techniques to perform elemental analysis in all kinds of samples, no matter if liquids, solids or loose powders must be analyzed.

XRF combines highest accuracy and precision with simple and fast sample preparation for the analysis of elements from Beryllium (Be) to Uranium (U) in the concentration range from 100 % down to the sub-ppm-level.

Energy dispersive X-ray fluorescence (EDXRF) is the best choice for dedicated applications in quality and process control with demands for ease of use and compact size. It delivers analytical flexibility for research and monitoring tasks.

Wavelength dispersive X-ray fluorescence spectrometry (WDXRF) is known for its unrivalled accuracy, precision and reliability. This robust analytical technology has made its way into all kinds of industrial applications, such as cement, polymers, refineries, mining, and industrial minerals.

X-ray fluorescence analysis (XRF) – one of the best analytical techniques to perform elemental analysis in all kinds of samples, no matter if liquids, solids or loose powders must be analyzed.

XRF combines highest accuracy and precision with simple and fast sample preparation for the analysis of elements from Beryllium (Be) to Uranium (U) in the concentration range from 100 % down to the sub-ppm-level.

Energy dispersive X-ray fluorescence (EDXRF) is the best choice for dedicated applications in quality and process control with demands for ease of use and compact size. It delivers analytical flexibility for research and monitoring tasks.

Wavelength dispersive X-ray fluorescence spectrometry (WDXRF) is known for its unrivalled accuracy, precision and reliability. This robust analytical technology has made its way into all kinds of industrial applications, such as cement, polymers, refineries, mining, and industrial minerals.

S2 RANGER X-ray Fluorescence

Unrivalled analytical performance with XFlash Technology

The S2 RANGER performs multi-element analysis from Carbon (C) to Uranium (U) from 100% down to the ppm-level in solids, powders or liquids with little or no sample preparation. Unrivalled analytical performance is ensured by using the highest power in direct excitation geometry.

The award-winning XFlash silicon drift detector technology, now available in its new generation XFlash V5, provides best energy resolution with highest count rates. The new XFlash V5 offers a larger active detector area which results in shorter measurement times and better detection limits. This unique combination of excitation and detection power guaranties good element separation, low detection limits, highest precision and best stability.

Determination of Low Sulfur in Automotive Fuels and Petroleum Products

In the refining process, sulfur concentrations are reduced from several percent in crude oil to low ppm levels in gasoline. This reduction requires close process control. To ensure and control petroleum product quality, sulfur analysis is also critical along the supply chain at pipelines, tank farms and customs.

The S2 RANGER with XFlash® SDD technology is the perfect match for the determination of low sulfur concentrations in automotive fuels and other petroleum products. Measurement reproducibility and long term stability data are excellent, showing how the S2 RANGER exceeds international standards for sulfur control.

Rapid process control by EDXRF with the S2 RANGER in cement

In the cement industry, production steps must be monitored closely on a daily basis in order to meet high demands on composition uniformity and overall product quality. In cement manufacturing, the S2 RANGER is well-suited as a supplementary system for process control.

The energy resolution and pulse processing performance of the XFlash® detector enable the S2 RANGER to measure not only the usual cement compounds in pellets but also to directly calculate cement modules, such as the Bogue compounds, C3S, C2S, C3A, and C4AF, and the ratios LSF, SM, and AM.

The S2 RANGER performs multi-element analysis from Carbon (C) to Uranium (U) from 100% down to the ppm-level in solids, powders or liquids with little or no sample preparation. Unrivalled analytical performance is ensured by using the highest power in direct excitation geometry.

The award-winning XFlash silicon drift detector technology, now available in its new generation XFlash V5, provides best energy resolution with highest count rates. The new XFlash V5 offers a larger active detector area which results in shorter measurement times and better detection limits. This unique combination of excitation and detection power guaranties good element separation, low detection limits, highest precision and best stability.

Determination of Low Sulfur in Automotive Fuels and Petroleum Products

In the refining process, sulfur concentrations are reduced from several percent in crude oil to low ppm levels in gasoline. This reduction requires close process control. To ensure and control petroleum product quality, sulfur analysis is also critical along the supply chain at pipelines, tank farms and customs.

The S2 RANGER with XFlash® SDD technology is the perfect match for the determination of low sulfur concentrations in automotive fuels and other petroleum products. Measurement reproducibility and long term stability data are excellent, showing how the S2 RANGER exceeds international standards for sulfur control.

Rapid process control by EDXRF with the S2 RANGER in cement

In the cement industry, production steps must be monitored closely on a daily basis in order to meet high demands on composition uniformity and overall product quality. In cement manufacturing, the S2 RANGER is well-suited as a supplementary system for process control.

The energy resolution and pulse processing performance of the XFlash® detector enable the S2 RANGER to measure not only the usual cement compounds in pellets but also to directly calculate cement modules, such as the Bogue compounds, C3S, C2S, C3A, and C4AF, and the ratios LSF, SM, and AM.

S8 TIGER X-ray Fluorescence

Technological innovation for wavelength dispersive X-ray fluorescence (WDXRF) spectrometry

The superior analytical performance of the S8 TIGER results from the innovative optimized X-ray optics. While the new high-intensity X-ray tube excites the sample even more efficiently, novel analyzer crystals for different elements and specific applications improve detection limits, precision and resolution. The high analytical performance and innovative ease of use of the S8 TIGER come in a very compact, attractive design.

S8 TIGER – the new high-end wavelength dispersive X-ray fluorescence (WDXRF) spectrometer

The S8 TIGER spectrometer is the innovative high-end addition to our XRF product family for elemental analysis in various industrial applications, including oil, lubricants, refinery, cement and mining.

Unique features of the S8 TIGER include TouchControl™ and SampleCare™, combining extreme ease of use and robust reliability with superior analytical performance. TouchControl is essential for easy and fail-safe operation. By using an integrated touch screen and dedicated user interface, TouchControl defines a new standard in ease of use for a high-end XRF system. The required training for occasional and inexperienced users is absolutely minimized. The unique SampleCare feature automatically recognizes samples and the integrated contamination shields protect the S8 TIGER against all kinds of contamination, ensuring maximum uptime and availability.

S8 TIGER – Superior analytical performance for elemental analysis

The S8 TIGER analyses all elements from Beryllium to Uranium in a wide variety of sample types. SPECTRAplus with the standardless analysis package QUANT-EXPRESS allows ultra-fast analysis of totally unknown samples.

The S8 TIGER is designed for demanding applications in industrial process and quality control, and as a powerful elemental analysis tool in research and development labs.

The superior analytical performance of the S8 TIGER results from the innovative optimized X-ray optics. While the new high-intensity X-ray tube excites the sample even more efficiently, novel analyzer crystals for different elements and specific applications improve detection limits, precision and resolution. The high analytical performance and innovative ease of use of the S8 TIGER come in a very compact, attractive design.

S8 TIGER – the new high-end wavelength dispersive X-ray fluorescence (WDXRF) spectrometer

The S8 TIGER spectrometer is the innovative high-end addition to our XRF product family for elemental analysis in various industrial applications, including oil, lubricants, refinery, cement and mining.

Unique features of the S8 TIGER include TouchControl™ and SampleCare™, combining extreme ease of use and robust reliability with superior analytical performance. TouchControl is essential for easy and fail-safe operation. By using an integrated touch screen and dedicated user interface, TouchControl defines a new standard in ease of use for a high-end XRF system. The required training for occasional and inexperienced users is absolutely minimized. The unique SampleCare feature automatically recognizes samples and the integrated contamination shields protect the S8 TIGER against all kinds of contamination, ensuring maximum uptime and availability.

S8 TIGER – Superior analytical performance for elemental analysis

The S8 TIGER analyses all elements from Beryllium to Uranium in a wide variety of sample types. SPECTRAplus with the standardless analysis package QUANT-EXPRESS allows ultra-fast analysis of totally unknown samples.

The S8 TIGER is designed for demanding applications in industrial process and quality control, and as a powerful elemental analysis tool in research and development labs.

Contact us

Syntech Innovation Co., Ltd.

388/5 Nuanchan Road, Nuanchan,

Buengkum, Bangkok 10230

388/5 Nuanchan Road, Nuanchan,

Buengkum, Bangkok 10230

0 2363 8585 (auto)

0 2363 8595

081 498 9939

3089199

Today

Yesterday

This Month

All days

157

1549

28907

3089199

Your IP: 216.73.216.80

2026-02-17 02:20